Energy saving electric screw press

electric screw press

Electric screw firebrick machine were equipment with 1. Brake device; 2. Maintenance platform; 3. Limit switch locating iron; 4. Froced lubrication system; 5. Guiderail; 6. Brake and ejection system control cabinet; 7. Servo control cabinet touch screen; 8. Servo control cabinet; 9. Digital electronic oil supply system; 10. Secondary hammer; 11. Water-cooled synchronous servo motor; 12.Maintenance ladder; 13. Bumper block; 14. Limit switch; 15. Slider; 16.Satety raster; 17. Intelligent button station; 18. Floating pressure workbench

E-Mail:haloong@haloong.com

Description

Summary&Structure:

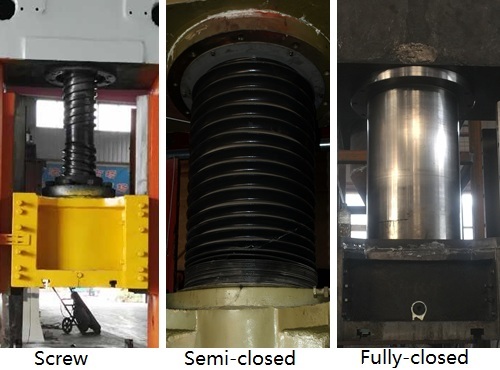

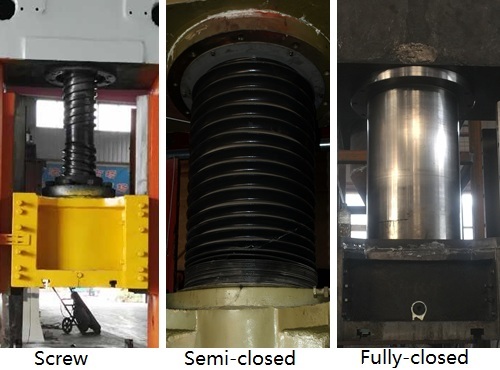

What in the picture we show you is HLDS-630T CNC servo press and HLDS-400T CNC servo press.they are semi-closed,servo cnc control,automatic lubricating system,multiple security grantee and one button operation,electric power is the mainly power source. Especially the screw were protect by a spring case to extend the lifespan of screw and machine.And we adopt servo motor then saving energy more than 65%,button operation to saving labor then just jone worker to finish the bricks work.Then they can also called as screw press,servo press,brick press,electric press,energy saving press machine,firebrick forming machine,refractory brick making press,fire brick making press.

Application:

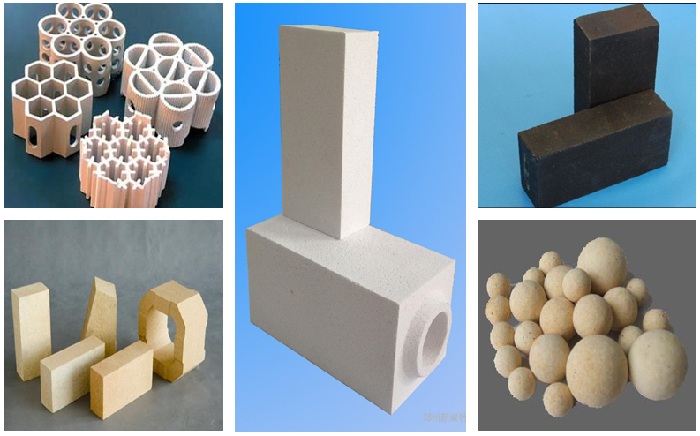

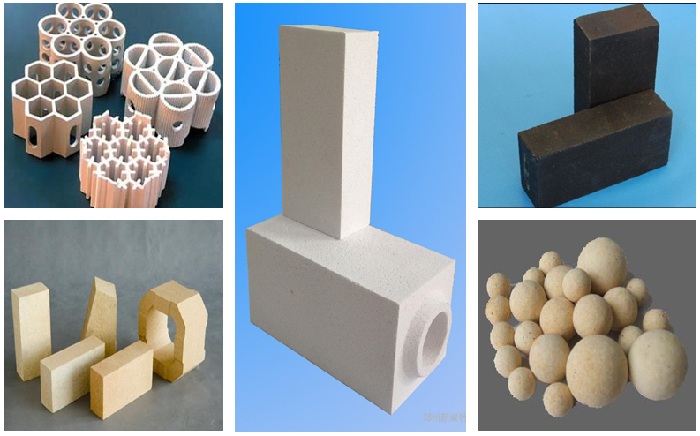

It is able to produce concrete bricks,high alumina bricks,high alumina corundum bricks,magnesia bricks,SiC bricks,acid resistance bricks, acid proof bricks, special shapped bricks, carbon bricks, carbon graphite bricks, magnesite carbon bricks, alumina carbon bricks, silicon carbide bricks, diatomite bricks, moler bricks, zircon corundum bricks, alkali resistant bricks, cyanite bricks, magnesite calcium carbon bricks, magnesia alumina bricks, magnesite chromite bricks, monolithic refractory bricks, refractory nozzle, zircon mollite bricks, chemically bonded magnesite chrome bricks, magnesite spinel bricks, mullite bricks, multi purpose refractories, superduty bricks, high duty bricks and etc

What in the picture we show you is HLDS-630T CNC servo press and HLDS-400T CNC servo press.they are semi-closed,servo cnc control,automatic lubricating system,multiple security grantee and one button operation,electric power is the mainly power source. Especially the screw were protect by a spring case to extend the lifespan of screw and machine.And we adopt servo motor then saving energy more than 65%,button operation to saving labor then just jone worker to finish the bricks work.Then they can also called as screw press,servo press,brick press,electric press,energy saving press machine,firebrick forming machine,refractory brick making press,fire brick making press.

Application:

It is able to produce concrete bricks,high alumina bricks,high alumina corundum bricks,magnesia bricks,SiC bricks,acid resistance bricks, acid proof bricks, special shapped bricks, carbon bricks, carbon graphite bricks, magnesite carbon bricks, alumina carbon bricks, silicon carbide bricks, diatomite bricks, moler bricks, zircon corundum bricks, alkali resistant bricks, cyanite bricks, magnesite calcium carbon bricks, magnesia alumina bricks, magnesite chromite bricks, monolithic refractory bricks, refractory nozzle, zircon mollite bricks, chemically bonded magnesite chrome bricks, magnesite spinel bricks, mullite bricks, multi purpose refractories, superduty bricks, high duty bricks and etc

Features of HLDS series CNC servo press:

Servo motor drive system:

Touch screen parameter setting system

Full automatic lubrication system

Multiple safety protection system

One button operating system

Touch screen parameter setting system

Full automatic lubrication system

Multiple safety protection system

One button operating system

| Parameter Table of Electric Screw Firebrick Press Machine | |||

| 1600t | nominal pressure 16000KN | 400B | nominal pressure 4000KN |

| max pressure 32000KN | max pressure 8000KN | ||

| slide stroke 860mm | slide stroke 750mm | ||

| stroke number 20 times | stroke number 28 times | ||

| worktable size 1700*1460mm | worktable size 1200*1050mm | ||

| motor for 272kw | motor for 50kw | ||

| double motor | single motor | ||

| weight for 118T | weight for 26T | ||

| 1200t | nominal pressure 12000KN | 800T | nominal pressure 8000KN |

| max pressure 24000KN | max pressure 16000KN | ||

| slide stroke 760mm | slide stroke 760mm | ||

| stroke number 22 times | stroke number 24 times | ||

| worktable size 1320*1140mm | worktable size 1300*1050mm | ||

| 168kw | motor for 100kw | ||

| double motors | double motors | ||

| weight 80T | weight for 56.8T | ||

| 1000t | nominal pressure 10000KN | 630t | nominal pressure 6300KN |

| max pressure 20000KN | max pressure 12000KN | ||

| slide stroke 760mm | slide stroke 780mm | ||

| stroke number 22 times | stroke number 26 times | ||

| worktable size 1300*1120mm | worktable size 1250*1050mm | ||

| motor for 78kw*2 | motor for 78kw 84kw | ||

| double motors | double motors | ||

| weight for 73.8T |

weight for 52T |

||

Online Message