![]()

![]()

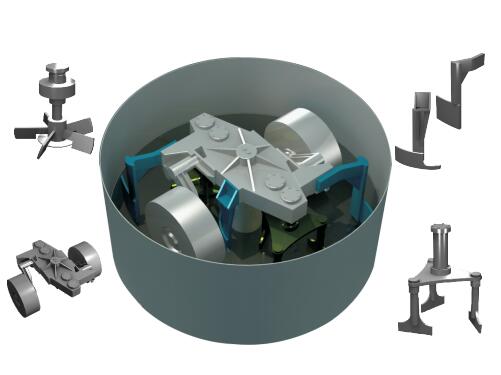

Haloong HXQ-1000 intensive mixing system consists of one pair of adjustable lifting grinding wheels, one pair of outer scrapers, one stirring horizontal rotator, one stereo high speed rotator and one inner scraper.

Working principle&features:

1.During working, the inner scraper pushes the material in the middle of grinding disk to the grind wheel workspace, the outer scraper cleans the material sticking on the wall and pushes the material on the edge of grinding disk to the grind wheel workspace for rolling and rubbing; then the stirring rotator blade stirs up the compacted material for stereo stirring.

2.Another high speed moving rotator generates a strong impact and friction between the materials, which makes the flake shape and needle-like particles reshape to aproximate positive cube. Thus the material can be fully homogenized, the water, fine power and binders combined effectively.

3.The whole process is no dead angle, achieves the best stirring effect. When mixing the unshaped castables, the grinding wheel will rise and do not move. Heating device can be equipped or not according to mixing requirements.

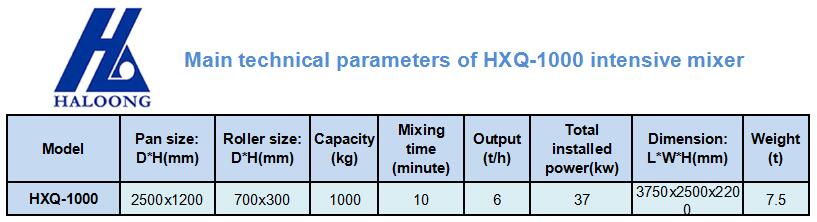

HXQ-1000 Mixing System

HXQ-1000 Mixing System

Consists 1 pair of adjustable lifing grinding wheels,1 pair of ourter scrapers,1 stirring horozontal rotator,1 stereo high speed rotator and 1 inner scraper.The whole process is no dead angle,achieves the best strirring effect.

E-Mail:haloong@haloong.com

Description

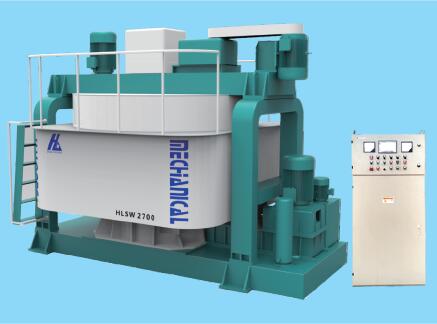

HXQ-1000 Intensive Mixing system

Summary&structure:

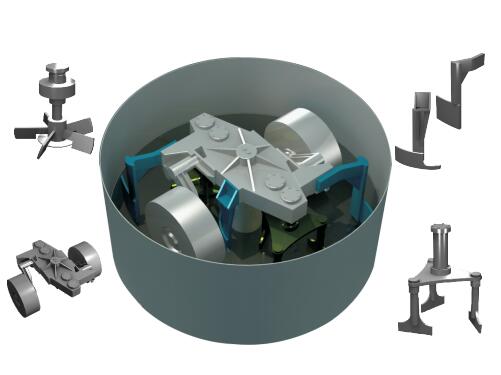

Haloong HXQ-1000 intensive mixing system consists of one pair of adjustable lifting grinding wheels, one pair of outer scrapers, one stirring horizontal rotator, one stereo high speed rotator and one inner scraper.

Working principle&features:

1.During working, the inner scraper pushes the material in the middle of grinding disk to the grind wheel workspace, the outer scraper cleans the material sticking on the wall and pushes the material on the edge of grinding disk to the grind wheel workspace for rolling and rubbing; then the stirring rotator blade stirs up the compacted material for stereo stirring.

2.Another high speed moving rotator generates a strong impact and friction between the materials, which makes the flake shape and needle-like particles reshape to aproximate positive cube. Thus the material can be fully homogenized, the water, fine power and binders combined effectively.

3.The whole process is no dead angle, achieves the best stirring effect. When mixing the unshaped castables, the grinding wheel will rise and do not move. Heating device can be equipped or not according to mixing requirements.

Online Message