产品中心

产品中心

Friction presses modification

1.Servo motor driving directly.

2.User can set the forming processing on the touch screen easily.

3.One button operation to complete the fire bricks producing;no radial force.

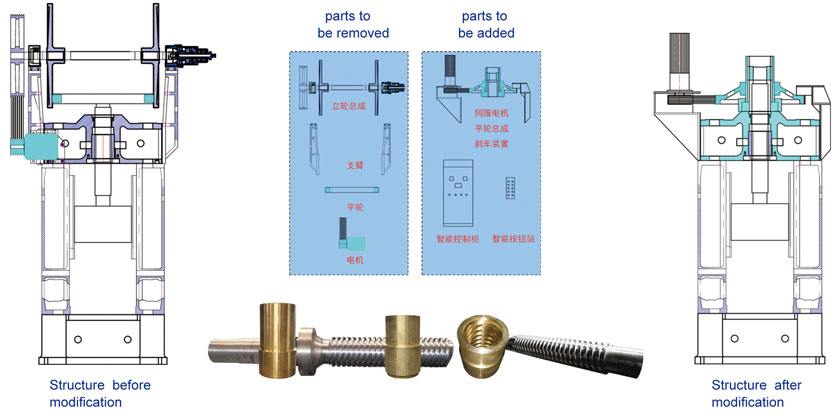

Modification from friction screw press to electrical screw press

In order to reduce the investment for production equipment, we can also make the modification from old type friction screw press to new electric screw press.

The old machine has the disadvantages of difficult in employment, high consumption, high noisy and high intensity labor for workers. After improved to be numerical control press, it has the features of easy to operate, low power consumption, few wear parts, good safety performa nce, stable quality and good product consistency, which is the revolutionary replacement product for refractory material industry. The pictures left of solution one and solution two are the drawings after improvement.

CNC presses compare with (double disk ) friction presses

High-level Automation

One button operation: no skilled operator needed, labor saved, the intensity of labor decreased, problem of production management solved

Servo control: freely convert between high speed and low speed in one stroke, completely simulate the manual stroke, effectively continous strokes

100% Qualified Products

Our press has achieved digital automatic control, and its energy and strokes can be controlled exactly. Product qualilty is no effected by human, so the products have high percent of pass.

Unique univeral making process, light strokes for exhaust and heave strokes for form. The press can make complex process and it can produce the specifical-shaped bricks and the checker bricks(37 holes or less than 37 holes).

Safety and Power-saved

Four-brakes and the safety raster optional. The 4 brakes can assure the effective braking in any state. There is urgent stop button in the control panel, if you press the button, the slide block can rise the highest point quickly.

The press can be started at very low current, so there is no effections for electricity. Our press can save about 50% power than friction press, so it can cut down large cost.

Maintain and Repair

To modify the friction press into servo press, it takes off the horizontal axis,setting-up wheels, support arms and assembly, shortens transmission chain, reduces the quick-wear parts, so the cost for maintain can reduce more than 35%.

After modification, there is no crosswise radial force, so the lifetime of bolts, screw and die can be extended.

Features after modification

- 1. Servo motor drives directly: numerically controls the power release precisely good product consistency and high qualified rate.

- 2. Touch screen sets the striking process easily: able to fully imitate the manual operation. Very fast continous punch speed improves production efficiency greatly.

- 3. One-button operation: automatically finish the whole technology process from material gently pressed for air-released to heavily press for product forming.

- 4. High degree automation makes it operate easily without experience.

- 5. High efficiency, power-saving high to 55%. Small start-up current has no impact for power grid.

- 6. After modification, the screw doesn't generate transverse radial force, which greatly improves the service life of transmission screw, screw nut and mould,then reduces the maintenance cost high to around 35%.

- 7. Mechanical and electrical multiple safety protection avoid accidents.

Customer production site

It is part of the enterprise transformation of the scene graph, Disadvantage of Friction Disk Screw Press: Long transmission chain and high power loss. More quickwear parts. Controlling is not accutate and labor-intensive. High power consumption. Big Noise . Low safety security. After transforming equipment, save people, save electricity, more secure.

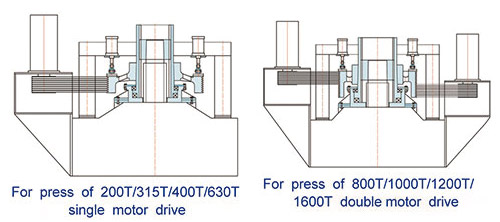

Product parameter

| reform to single drive | 30T | 200T | 315T | 400T | 630T |

| reform to double drives | 800T | 1000T | 1200T | 1600T |