How to identify the performance of servo press? Tom or Jerry

Author: haloong Time: 2017-04-12 17:26

The Pressurization mechanism of servo press machine usually classify to Crankshaft, no crankshaft, crankshaft + connecting rod, screw type,while Most of the crankshaft.

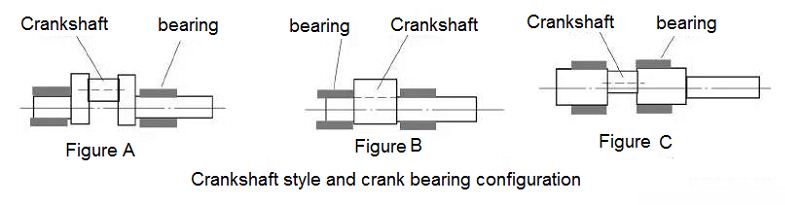

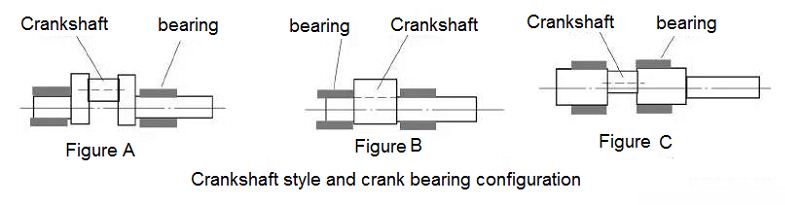

Figure A, you can adjust the crankshaft bearing spacing and crankshaft shaft thickness, etc. to reduce its bending deformation. Due to the different size of the crankshaft of the nominal force, the size of the eccentricity in the crankshaft form is also different. Figure B, when subjected to stamping load bending deformation is small, this form of the use of the crankshaft bearings can be placed closer to the crankshaft position, which has the advantage of reducing bending deformation. Figure A is used in the form of stroke length of less than 250mm, Figure B for stroke length of 150mm or less, Figure C for stroke length of 50mm or less within the press.

The performance of the servo press machines are effected by followings, the bearing rack of stamping load, the elongation of press rack, the defection of deflection of slide block and pedestal, the deflection of slide rail, the size of hole on pedestal and the thickness of workbench.Especially for servo press machine,It’s very necessary to reduce elongation and deflection deformation,enhance the rigidity of the slider, and control the base opening under the minimum necessary, increase the thickness of the work table as much as possible.If all these indicators are good, the performance of machines can be fully exploited.

Sometimes, the mold cushioning device (with the top pin) conveys the pressure from the cushion to the platen (blanket plate) of the mold and uses at least four pin pins for deep drawing of the small parts. When the cylinder is deepened, the load acting on the four pin (the pressing force of the plate) is the same. In fact, due to the accuracy of the press machine, the rigidity, the different form of the rack Bear the load are different, the middle of almost no load (load is zero), that is to say there are some cases where the pin is vacant. When the load on the top pin is not the same, the compression deformation of each pin will be different and the balance of the platen will change. In the stamping process, do not see the action of the pressure plate what is abnormal, but if the different parts of the roof to install a few sensors, the actual stamping work conditions after the measurement, you will find the pressure plate in the vibration, beating, almost no The most common cause of this phenomenon is the impact of the upper mold on the platen. The medium in which the pressure is generated in the mold cushioning device is compressed air or oil pressure, and most of the molds are a compressed air type air spring. The vibration of the car during walking is caused by the shock absorber and the spring acting together to absorb the attenuation, but there is no shock absorber on the mold cushioning device on the press. Therefore, the vibration generated from the impact of the upper mold is not attenuated in the press working, so that the drawing process is carried out in the vibration state of the mold cushioning device. It is easy to think that the drawing is carried out without the implementation of the correct pressure, is not stable. With such a simple small cylinder drawing process is carried out in the above state, then, in the automotive cover this large size, complex shape, coupled with the composite material thickness, and the strength of the material is also different parts, deep drawing , It is necessary to use the diameter of φ 50 ~ φ70mm, the length of 700 ~ 1000mm in the top pin, and the need for more than 20. In summary, from the servo press machine itself, the performance of the servo press machine , it is necessary to control the vibration at the lowest, which is the servo compressor system design an important part.

Lubrication system, which is a common problem for all machines, it is particularly important for proper lubrication with suitable clearance for NC controlled servo presses. To make such servo press machine could be stable operation,which with small gap and heavy load.not only need to clean the oil, full cooling function is also essential. Mechanical gap, you can relatively light operation, but can not get the servo press must achieve the excellent accuracy. To make the crankshaft in the load can also run smoothly, the gap between the crankshaft is also very critical, which gives the mechanical precision machining, that is, the technical level of mechanical processing put forward a high demand, of course, this is all the work Machinery is applicable.

servo press machine lubrication system must be more than the traditional requirements of the ordinary press lubrication system much higher Caixing. Otherwise, it will lose the actual function and convenience of the servo press machine . Such as the use of servo press machine free swing operation function, you need to crankshaft, gear and other special lubrication, these must be taken into account in the design.

Figure A, you can adjust the crankshaft bearing spacing and crankshaft shaft thickness, etc. to reduce its bending deformation. Due to the different size of the crankshaft of the nominal force, the size of the eccentricity in the crankshaft form is also different. Figure B, when subjected to stamping load bending deformation is small, this form of the use of the crankshaft bearings can be placed closer to the crankshaft position, which has the advantage of reducing bending deformation. Figure A is used in the form of stroke length of less than 250mm, Figure B for stroke length of 150mm or less, Figure C for stroke length of 50mm or less within the press.

The performance of the servo press machines are effected by followings, the bearing rack of stamping load, the elongation of press rack, the defection of deflection of slide block and pedestal, the deflection of slide rail, the size of hole on pedestal and the thickness of workbench.Especially for servo press machine,It’s very necessary to reduce elongation and deflection deformation,enhance the rigidity of the slider, and control the base opening under the minimum necessary, increase the thickness of the work table as much as possible.If all these indicators are good, the performance of machines can be fully exploited.

Sometimes, the mold cushioning device (with the top pin) conveys the pressure from the cushion to the platen (blanket plate) of the mold and uses at least four pin pins for deep drawing of the small parts. When the cylinder is deepened, the load acting on the four pin (the pressing force of the plate) is the same. In fact, due to the accuracy of the press machine, the rigidity, the different form of the rack Bear the load are different, the middle of almost no load (load is zero), that is to say there are some cases where the pin is vacant. When the load on the top pin is not the same, the compression deformation of each pin will be different and the balance of the platen will change. In the stamping process, do not see the action of the pressure plate what is abnormal, but if the different parts of the roof to install a few sensors, the actual stamping work conditions after the measurement, you will find the pressure plate in the vibration, beating, almost no The most common cause of this phenomenon is the impact of the upper mold on the platen. The medium in which the pressure is generated in the mold cushioning device is compressed air or oil pressure, and most of the molds are a compressed air type air spring. The vibration of the car during walking is caused by the shock absorber and the spring acting together to absorb the attenuation, but there is no shock absorber on the mold cushioning device on the press. Therefore, the vibration generated from the impact of the upper mold is not attenuated in the press working, so that the drawing process is carried out in the vibration state of the mold cushioning device. It is easy to think that the drawing is carried out without the implementation of the correct pressure, is not stable. With such a simple small cylinder drawing process is carried out in the above state, then, in the automotive cover this large size, complex shape, coupled with the composite material thickness, and the strength of the material is also different parts, deep drawing , It is necessary to use the diameter of φ 50 ~ φ70mm, the length of 700 ~ 1000mm in the top pin, and the need for more than 20. In summary, from the servo press machine itself, the performance of the servo press machine , it is necessary to control the vibration at the lowest, which is the servo compressor system design an important part.

Lubrication system, which is a common problem for all machines, it is particularly important for proper lubrication with suitable clearance for NC controlled servo presses. To make such servo press machine could be stable operation,which with small gap and heavy load.not only need to clean the oil, full cooling function is also essential. Mechanical gap, you can relatively light operation, but can not get the servo press must achieve the excellent accuracy. To make the crankshaft in the load can also run smoothly, the gap between the crankshaft is also very critical, which gives the mechanical precision machining, that is, the technical level of mechanical processing put forward a high demand, of course, this is all the work Machinery is applicable.

servo press machine lubrication system must be more than the traditional requirements of the ordinary press lubrication system much higher Caixing. Otherwise, it will lose the actual function and convenience of the servo press machine . Such as the use of servo press machine free swing operation function, you need to crankshaft, gear and other special lubrication, these must be taken into account in the design.