Discussion on advantages of servo cnc electric screw press

Author: haloong Time: 2018-07-26 11:35:43

Servo cnc electric screw press has many advantages in performance. It has been recognized in metal forming industry and refractory products industry and has been accepted by more and more enterprises. With high quality, low price, simple, reliable and a series of advantages, using its good rigidity, high reliability, and productivity in the service of mass production of various industrial departments, and is also low maintenance cost, high efficiency. Although it is unlikely that all presses will be servo-driven in the future. However, servo motor drive brings a series of advantages to the press, especially flexibility, energy saving and noise reduction.

1. Application forms of servo technology on press machines

In a broad sense, the press machine that uses servo motor instead of flywheel clutch driving slider can be called servo motor press. At present due to the forging press complex mechanical structure, servo press refers to the mechanical press is no longer use the flywheel and clutch, but uses the direct-drive servo motor, thus promote the slider movement up and down. The deformation force and energy of the press no longer depend on the flywheel’s energy storage, but are provided directly by the torque of the servo motor. Because it is driven directly by the servo motor, it can control the stroke, speed and acceleration of the slider accurately by controlling the output of the servo motor.

The servo drive press using servo drive technology is generally called servo press. The following also refer to servo direct drive press.

2. Advantages of servo cnc electric screw press

Compared with the traditional clutch flywheel press, the servo cnc electric screw press has obvious advantages in product forming, automatic realization, mould life, energy utilization, failure rate and other aspects.

2.1 advantages 1: expand the production range of product materials and complex products

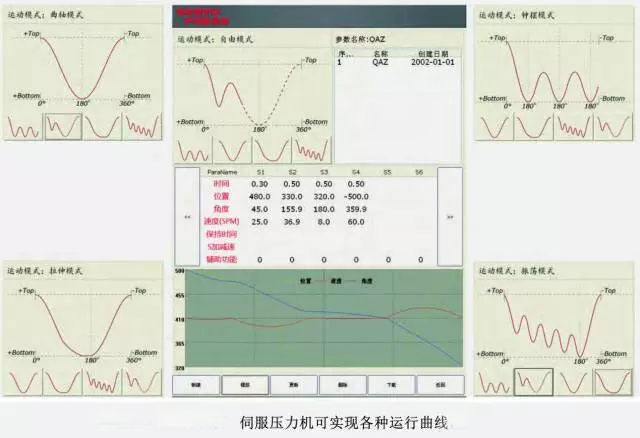

The speed of slider curve and slider can be adjusted freely. There are many different operating modes in the system. Customers can choose according to the different requirements of the forged products or set them by themselves. The speed can be set as the forming speed suitable for a certain material, and it can be set at any time and at any stroke to maintain the pressure, thus greatly expanding the range of pressable products.

Because of servo motor direct drive technology is servo motor output torque to the slider, unlike the limitation of the flywheel energy decrease, provided by forming energy is larger, can realize extrusion, such as deep drawing process. And can replace the hydraulic press for high - strength steel hot forming.

At the same time, the servo drive technology can also realize the load stroke in the deformation force range like hydraulic press.

The servo press can realize various operating curves

2.2 advantage 2: improve mould life

The mould life is closely related to the contact speed between the mould and the blank. Too high speed, forming impact, will shorten the mould life. By adopting servo drive technology, the speed of the slider can be set to ensure flexible contact between the mould and the blank, so as to effectively improve the mould life.

2.3 advantage 3: completely solve the problem of the press machine jammed, the mold debugging is simple and quick

Servo motor comes with a torque anomaly detection function, in the process of operation such as abnormal torque (pressure), will be to respond in a timely manner, motor reversal, slider return, thus completely solve the press jammed problems. At the same time, the safety protection of workers has been greatly increased.

The servo motor can move up and down or stop at any speed when the slider is under full load, which greatly shortens the time of mould debugging and makes mould debugging simple and fast.

2.4advantages 4: simple structure, low failure rate and easy maintenance

According to statistics, the reasons why enterprises are reluctant to use mechanical presses are mainly complicated structure and high failure rate, among which nearly 50% of faults come from the clutch. Servo CNC machine adopt servo motor directly with the retarding mechanism of gear connection, no longer need the clutch and the flywheel is faulty parts, simple structure, easy to maintain, running low failure rate, maintenance is convenient.

2.5 advantage 5: easy to realize the automation of the whole machine

Servo CNC press slider curve can be arbitrarily set and changes, its characteristic is easy to satisfy the walking beam, robot, mold spray requirement of online automatic, easy to realize automation of the press, stable and reliable running.

2.6 advantage 6: energy saving, vibration reduction, noise reduction and environmental protection

Compared with traditional flywheel clutch servo press, the servo motor can be according to the slider speed curve to realize variable speed or stop at any time, to avoid the idling energy consumption, energy saving effect in more than 50%. Because the clutch flywheel and other parts are no longer needed, the noise and vibration are effectively reduced. It is a kind of truly environment-friendly mechanical press.

2.7 advantage 7: improve production efficiency

By setting the curve of the sliding block, the sliding block can rapidly descend and return, shorten the working cycle, and effectively improve the production efficiency.

Servo cnc electric screw press is a new generation of press which is completely different from the traditional mechanical press. It is a combination of information technology, automatic control technology and traditional machinery technology. The appearance of servo press makes it possible to use more new materials for product forming, which not only expands more high value-added products, but also lays a foundation for automation.