Development and Workflow of Refractory Brick Press machine

Author: haloong Time: 2017-04-20 16:39:19

China's refractory equipment development is relatively slow, with the introduction of advanced Western technology and China's scientific and technological progress, refractory technology has been greatly improved. At present, China has developed a variety of advanced refractory brick equipment, which not only reflects the rapid development of China's mechanical engineering technology, but also make up for China's refractory technology deficiencies for the development of China's refractory industry has added unlimited power The

Refractory brick press machine is the most widely used refractory equipment in China, with high automation, high efficiency, low labor intensity, multi-function advantages, the development potential, the market prospects are good, is the promotion of the use of high-quality refractory brick equipment The So, do you know the production process of refractory press machine?

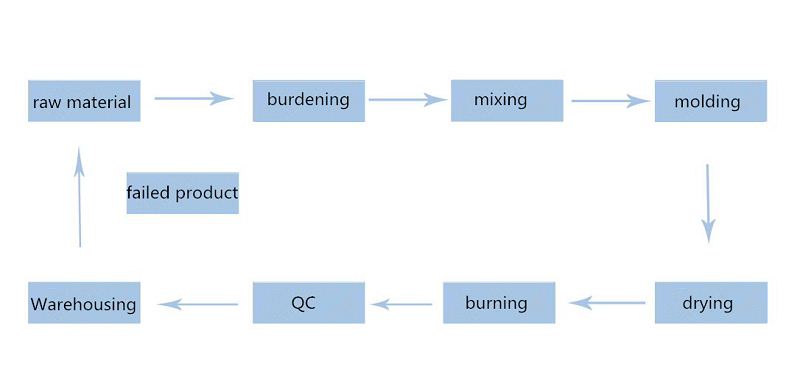

1, raw materials processing: refractory brick production of raw materials (silica, clay, bauxite, magnesite, etc.) generally have to go through the first mineral processing, crushing and screening, to achieve the raw material production process standards can be reasonable produce.

2, ingredients: the production of refractory bricks of various raw materials by a reasonable way to measure the proportion of measurement, adding a certain percentage of water or other binding agent made of effective raw materials.

3, mixing: the ratio of raw materials in the wheel under the action of the full mixing of mixing, to achieve uniform material state.

4, molding: hydraulic press through the high pressure will be prepared a good raw materials for molding process, made of a certain size, shape and strength of brick.

5, dry: the formation of brick will be dry, to improve the strength of brick, more convenient to install the kiln, is conducive to the next step of the sintering process can be carried out smoothly.

6, firing: the brick will be dried after the tunnel into the tunnel kiln for sintering maintenance, improve the compressive strength of brick and bending strength.

7, inspection: the kiln after the brick for the finished product inspection, confirmed before passing the mass production.

8, finished product storage: the inspection of qualified products shipped to the finished product library to complete the whole round of production of defective products to be back to the first process, from the new raw materials processing.

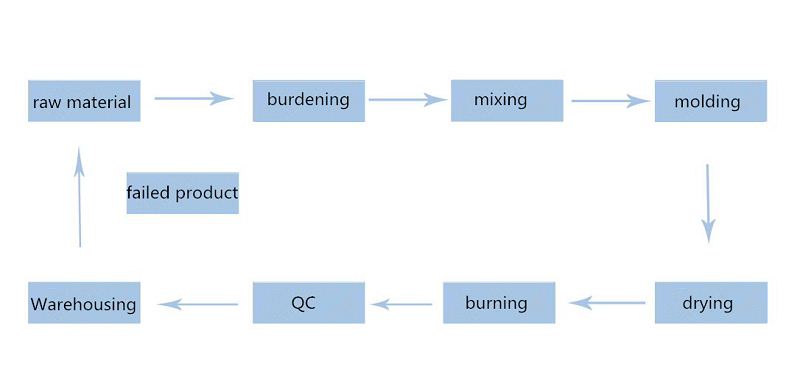

Refractory brick press machine is the most widely used refractory equipment in China, with high automation, high efficiency, low labor intensity, multi-function advantages, the development potential, the market prospects are good, is the promotion of the use of high-quality refractory brick equipment The So, do you know the production process of refractory press machine?

1, raw materials processing: refractory brick production of raw materials (silica, clay, bauxite, magnesite, etc.) generally have to go through the first mineral processing, crushing and screening, to achieve the raw material production process standards can be reasonable produce.

2, ingredients: the production of refractory bricks of various raw materials by a reasonable way to measure the proportion of measurement, adding a certain percentage of water or other binding agent made of effective raw materials.

3, mixing: the ratio of raw materials in the wheel under the action of the full mixing of mixing, to achieve uniform material state.

4, molding: hydraulic press through the high pressure will be prepared a good raw materials for molding process, made of a certain size, shape and strength of brick.

5, dry: the formation of brick will be dry, to improve the strength of brick, more convenient to install the kiln, is conducive to the next step of the sintering process can be carried out smoothly.

6, firing: the brick will be dried after the tunnel into the tunnel kiln for sintering maintenance, improve the compressive strength of brick and bending strength.

7, inspection: the kiln after the brick for the finished product inspection, confirmed before passing the mass production.

8, finished product storage: the inspection of qualified products shipped to the finished product library to complete the whole round of production of defective products to be back to the first process, from the new raw materials processing.