Evolution process of electric screw press machine(I)

Author: haloong Time: 2017-05-09 17:38:58

Screw press is one of the oldest forming equipment, has a very long history of development. A long time ago, there was a wooden screw press in Europe to suppress grape juice and olive oil. 15th century German Johann Gensleisch made a spiral press on a wooden screw press, which can be said to be the ancestors of screw presses and other mechanical presses. In the European language, the press and the printing of the two words with the root. At the beginning of the 16th century, the Italians used metal presses to suppress metal works of art and coins. Figure 1 for the 18th century by the manpower-driven screw press. Until the mid- 19th century there was a steam-driven mechanical press.

The first screwdriver used in modern industrial production by friction plate transmission power, referred to as friction press, which began in the early 19th century, because the structure is simple, reliable, friction press is still in use. The biggest drawback is the low efficiency of friction transmission, about 50% to 55%, the total efficiency of about 20% to 25%. In the past century, people have been looking for improved methods, the main objectives are: 1. To improve transmission efficiency, reduce energy consumption; 2. Increase equipment tonnage, improve work ability; 3. Improve the combat energy control accuracy and operation of the degree of automation

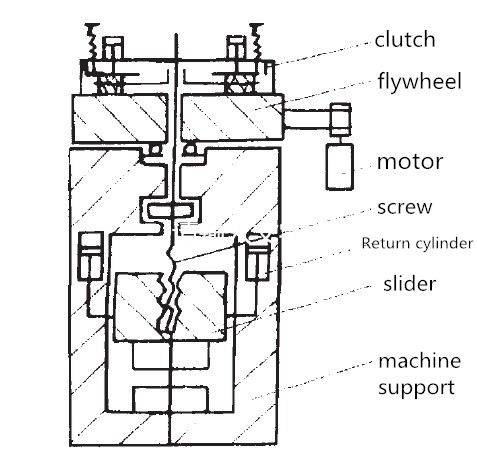

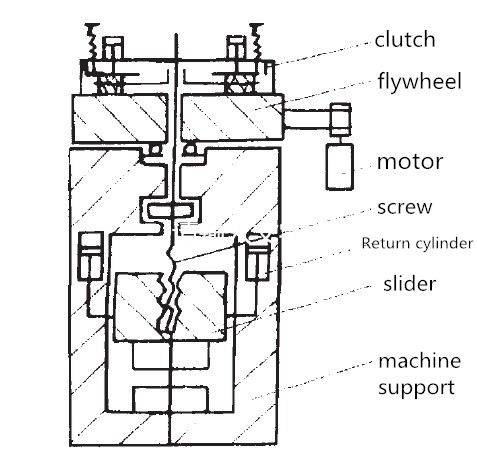

The twentieth century is the period of rapid development of spiral presses. In the 1920s, people began to develop hydraulic screw presses, and were put into industrial applications in the late 1940s. In the 1930s, the former Soviet Union began the development of electric screw presses, Germany began production in the late 1950s, and by the end of the 1970s, the company developed a successful clutch screw press. At the end of the 20th century, Japan Enomoto company developed a servo drive motor screw press.

Into the 21st century,this old forming equipment- hydraulic screw press is still booming, has formed a variety, complete specifications, the degree of automation gradually fade for the development of human civilization continue to contribute.

The first screwdriver used in modern industrial production by friction plate transmission power, referred to as friction press, which began in the early 19th century, because the structure is simple, reliable, friction press is still in use. The biggest drawback is the low efficiency of friction transmission, about 50% to 55%, the total efficiency of about 20% to 25%. In the past century, people have been looking for improved methods, the main objectives are: 1. To improve transmission efficiency, reduce energy consumption; 2. Increase equipment tonnage, improve work ability; 3. Improve the combat energy control accuracy and operation of the degree of automation

The twentieth century is the period of rapid development of spiral presses. In the 1920s, people began to develop hydraulic screw presses, and were put into industrial applications in the late 1940s. In the 1930s, the former Soviet Union began the development of electric screw presses, Germany began production in the late 1950s, and by the end of the 1970s, the company developed a successful clutch screw press. At the end of the 20th century, Japan Enomoto company developed a servo drive motor screw press.

Into the 21st century,this old forming equipment- hydraulic screw press is still booming, has formed a variety, complete specifications, the degree of automation gradually fade for the development of human civilization continue to contribute.