(2) Dose smog corrode the press machinery ?

Author: haloong Time: 2016-12-30 12:53:44

China corrosion and protection network: speed up the corrosion of metal objects, the main factors which?

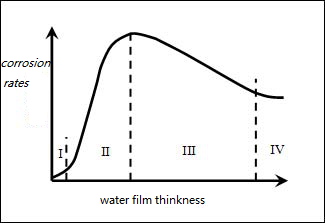

There are many factors influencing the corrosion rate of metal materials in the atmospheric environment, among which humidity is one of the most important factors. According to the humidity of the metal surface, that is, according to the presence or absence of the electrolyte layer and the state, the atmospheric corrosion is usually divided into three categories: dry atmospheric corrosion, tidal atmospheric corrosion and wet atmospheric corrosion, different atmospheric types of metal corrosion rate difference Great. The graph below characterizes the relationship between the atmospheric corrosion rate and the film thickness on the metal surface.

The Relationship between Atmospheric Corrosion Velocity and Water Film Thickness on Metal Surface

Area I: In the case of particularly low atmospheric humidity, the metal surface only a thin film of water adsorption, up to only a few molecular thickness (1 ~ 10nm), can not be considered a continuous electrolyte. This area is equivalent to dry atmospheric corrosion, corrosion rate is very low.

Area II: With the increase of humidity in the atmosphere, the thickness of the liquid film on the metal surface gradually increased, the water film thickness up to tens or hundreds of layers of water molecules to form a continuous electrolyte thin layer, began a continuous electrochemical corrosion process . This area corrosion rate increased sharply, the equivalent of tidal atmospheric corrosion.

Area III: When the metal surface water film layer continues to increase to a few microns thick, into the wet atmospheric corrosion zone. Since the diffusion of oxygen through the liquid film to the metal surface becomes difficult with the thickening of the liquid film, the corrosion rate decreases with the thickness of the liquid film in this region.

Area IV: When the metal surface water film layer becomes thicker (such as greater than 1mm), has been equivalent to full immersion in the electrolyte corrosion, corrosion rate is basically unchanged. In the actual atmospheric environment, usually more corrosion in the II, III region, due to changes in environmental conditions, a variety of forms of corrosion can be converted to each other.

Thus, the corrosion rate of metal and atmospheric humidity are closely related, generally speaking, the greater the humidity in the air, the metal surface condensation more easily, the surface of the electrolyte membrane is also longer, the corrosion rate increased accordingly. All kinds of metals have a corrosion rate began to sharply increase the humidity range, so that the metal atmospheric corrosion rate began to sharply increase the relative humidity of the atmosphere known as the critical humidity. Iron, copper, nickel, zinc and other metals, the critical humidity of about 50% to 70%. It can be seen that if the relative humidity of 60% or more, the corrosion of steel increased sharply; and less than 60% when the corrosion is small.

Zhengzhou Haloong Machinery Manufacturing Co., Ltd. is specilized in Servo Press machinery, electric screw press machine,firebrick press machine,refractory brick press machine,metal forging press machine,clay brick press machine,CNC power press,double disk friction press reform for 35years.

email:haloong@haloong.com

Ph:+008613083696911.

tell:+86-371-60121717

wechat:308484547;

skype: crystalmingming;

QQ:308484547

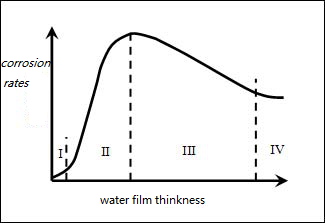

There are many factors influencing the corrosion rate of metal materials in the atmospheric environment, among which humidity is one of the most important factors. According to the humidity of the metal surface, that is, according to the presence or absence of the electrolyte layer and the state, the atmospheric corrosion is usually divided into three categories: dry atmospheric corrosion, tidal atmospheric corrosion and wet atmospheric corrosion, different atmospheric types of metal corrosion rate difference Great. The graph below characterizes the relationship between the atmospheric corrosion rate and the film thickness on the metal surface.

The Relationship between Atmospheric Corrosion Velocity and Water Film Thickness on Metal Surface

Area I: In the case of particularly low atmospheric humidity, the metal surface only a thin film of water adsorption, up to only a few molecular thickness (1 ~ 10nm), can not be considered a continuous electrolyte. This area is equivalent to dry atmospheric corrosion, corrosion rate is very low.

Area II: With the increase of humidity in the atmosphere, the thickness of the liquid film on the metal surface gradually increased, the water film thickness up to tens or hundreds of layers of water molecules to form a continuous electrolyte thin layer, began a continuous electrochemical corrosion process . This area corrosion rate increased sharply, the equivalent of tidal atmospheric corrosion.

Area III: When the metal surface water film layer continues to increase to a few microns thick, into the wet atmospheric corrosion zone. Since the diffusion of oxygen through the liquid film to the metal surface becomes difficult with the thickening of the liquid film, the corrosion rate decreases with the thickness of the liquid film in this region.

Area IV: When the metal surface water film layer becomes thicker (such as greater than 1mm), has been equivalent to full immersion in the electrolyte corrosion, corrosion rate is basically unchanged. In the actual atmospheric environment, usually more corrosion in the II, III region, due to changes in environmental conditions, a variety of forms of corrosion can be converted to each other.

Thus, the corrosion rate of metal and atmospheric humidity are closely related, generally speaking, the greater the humidity in the air, the metal surface condensation more easily, the surface of the electrolyte membrane is also longer, the corrosion rate increased accordingly. All kinds of metals have a corrosion rate began to sharply increase the humidity range, so that the metal atmospheric corrosion rate began to sharply increase the relative humidity of the atmosphere known as the critical humidity. Iron, copper, nickel, zinc and other metals, the critical humidity of about 50% to 70%. It can be seen that if the relative humidity of 60% or more, the corrosion of steel increased sharply; and less than 60% when the corrosion is small.

Zhengzhou Haloong Machinery Manufacturing Co., Ltd. is specilized in Servo Press machinery, electric screw press machine,firebrick press machine,refractory brick press machine,metal forging press machine,clay brick press machine,CNC power press,double disk friction press reform for 35years.

email:haloong@haloong.com

Ph:+008613083696911.

tell:+86-371-60121717

wechat:308484547;

skype: crystalmingming;

QQ:308484547