Application of servo electric screw press in the production process of firebrick at lower water outlet

Author: haloong Time: 2024-03-02 15:09:35

In the refractory industry, as an important part of the kiln, the quality and performance of the downwater refractory brick are crucial to the long-term stable operation of the kiln. Tangshan Guoliang Refractory Co., LTD., as a leader in the industry, has been committed to improving the production technology and product quality of refractory bricks under water. In recent years, they have successfully introduced servo electric screw presses, which have realized the innovation and optimization of the production process.

In the production process of traditional lower water outlet refractory brick, the molding link often relies on manual operation and experience judgment, which leads to low dimensional accuracy and unstable internal structure, which seriously affects the performance of the product. In order to solve this problem, Tangshan Guoliang decided to introduce servo electric screw presses to improve product quality and production efficiency through automation and precise control.

Servo electric screw press has many advantages, such as high precision, high efficiency, energy saving and environmental protection, and can realize the precise control of pressure and speed to ensure that each piece of water inlet firebrick can achieve the best forming effect. In addition, the equipment also has a high degree of automation, easy operation and other characteristics, greatly reducing the labor intensity of workers, improve the production efficiency.

After the introduction of the servo electric screw press, Tangshan Guoliang has comprehensively optimized the production process. They first carry out strict screening and treatment of raw materials to ensure the quality and uniformity of raw materials. Then, through the precise dosing and mixing process, the firebrick raw materials that meet the requirements are prepared.

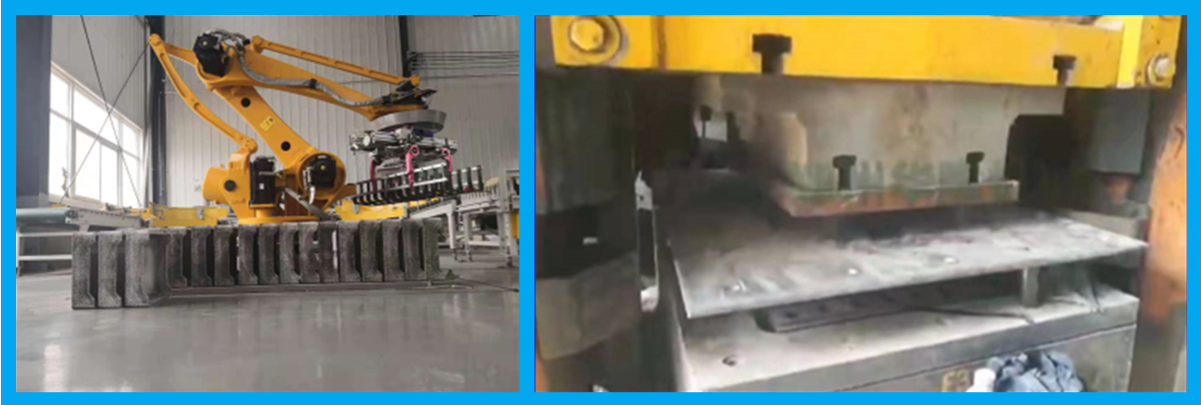

In the forming process, the servo electric screw press has played a huge role. Workers only need to put the raw materials into the mold, set the pressure and speed parameters, and the equipment can automatically complete the molding process. This precise molding method not only improves the dimensional accuracy and internal structural stability of the product, but also greatly reduces the production cycle.

In addition, the high efficiency of the servo electric screw press has also significantly improved the production capacity of Tangshan Guoliang. Compared with the traditional molding equipment, the equipment has a faster response speed and higher production efficiency, so that Tangshan Guoliang can quickly meet the market demand.

By introducing the servo electric screw press and optimizing the production process, Tangshan Guoliang successfully realized the innovation of the production process of the refractory brick at the lower water inlet. The newly produced firebrick not only has higher dimensional accuracy, more stable internal structure, but also has higher density and durability. These high-quality products have been recognized and praised by the majority of customers, and won more market share for Tangshan Guoliang.