Annual output of 100,000 tons of magnesia carbon brick production line

Author: haloong Time: 2024-01-08 11:55:41

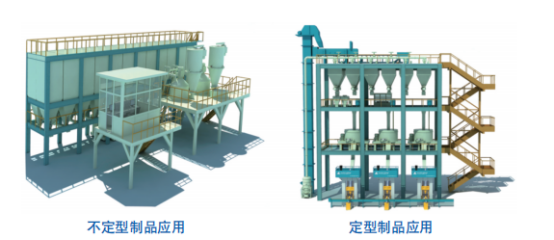

This project provides a fully automated magnesia-carbon brick production line based on servo electric screw press, which can achieve an annual output of 100,000 tons. The line integrates functions such as automatic cloth, automatic brick taking and automatic palletizing to improve production efficiency, reduce labor costs and ensure product quality.

Second, equipment configuration

Servo electric screw press: As the core equipment of the production line, it is used for pressing and forming magnesium carbon bricks. Advanced servo control system can achieve high precision and high efficiency pressing.

Automatic cloth system: the raw materials are uniformly fed into the mold through the conveyor belt to ensure the stability of the pressing process and the consistency of the product. Automatic brick taking equipment: The use of mechanical arm and vacuum suction and other technologies to achieve rapid and accurate grasp of magnesia-carbon bricks.

Automatic palletizing system: Using conveyor belts and stackers, the pressed magnesia-carbon bricks are neatly placed together for subsequent storage and transportation.

Central control system: used to monitor the running status of the entire production line, to achieve the coordinated operation and data management of each equipment.

3. Process flow

Preparation of raw materials: Prepare magnesia, carbon materials and other raw materials according to the formula ratio.

Automatic distribution: The raw material is evenly fed into the mold through the conveyor belt. Servo electric screw

Press pressing: Under the press of servo electric screw press, the raw material is formed into magnesia-carbon brick.

Automatic brick removal: Mechanical arms and vacuum suction cups grab magnesia-carbon bricks to avoid manual contact and improve efficiency and safety.

Automatic palletizing: the magnesia-carbon bricks are neatly placed on the tray for easy storage and transportation.

Quality inspection: Quality inspection of magnesia carbon brick to ensure product quality.

Packing and warehousing: Qualified products are packaged and stored in the warehouse.

4. Advantages and characteristics

Fully automated production: from raw material preparation to product packaging warehousing, the whole process of automatic operation, reducing labor costs.

High efficiency production: The selection of servo electric screw presses and other equipment ensures high efficiency production capacity.

Precise control: The central control system carries out real-time monitoring and data management of the entire production line to ensure the stability of product quality.

Safe and reliable: Automatic brick taking and palletizing equipment avoid manual contact and improve the safety of production.