How does the electric screw press optimize the quality of refractory products?

Author: haloong Time: 2024-01-05 11:35:20

As an indispensable and important material in the field of high temperature industry, the quality of refractory materials is directly related to the operation efficiency and safety performance of related equipment. The electric screw press, as an advanced molding equipment, plays an important role in the production of refractory materials and can significantly optimize product quality. The following, combined with the actual production case, describes in detail how to optimize the quality of the electric screw press refractory products.

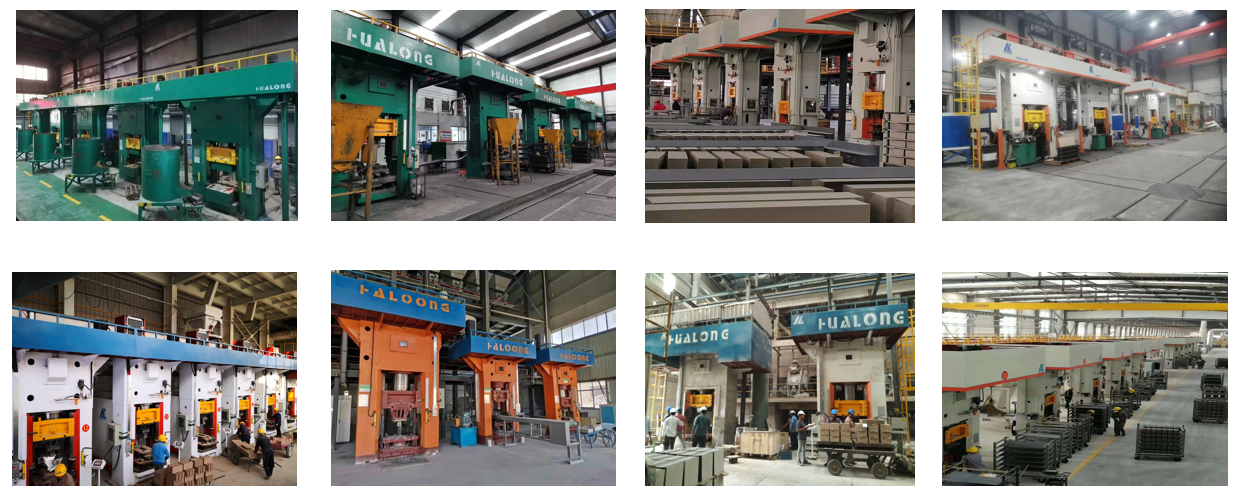

In the production line of a refractory production enterprise, the traditional molding equipment has problems such as loose structure, uneven density and unstable performance due to backward technology and complex operation. This not only affects the service life of the product, but also brings safety risks to customers. In order to solve these problems, the company introduced an electric screw press for forming production.

Through the use of electric screw press molding, the company achieved continuous and efficient production of refractory products. The electric screw press drives the screw mold through the motor to press the refractory powder uniformly and tightly into the product of the desired shape. Because the electric screw press has a precise control system, it can realize the accurate adjustment of the pressure, speed and other parameters, so as to ensure the molding accuracy and stability of the product.

In actual production, the company found that after the use of electric screw presses, the density of refractory products is significantly increased, and the structure is more dense and uniform. At the same time, the performance of the product has also been significantly improved, such as high temperature resistance, corrosion resistance, etc., has been significantly improved. This is mainly due to the unique forming principle and precise control system of the electric screw press.

In addition, the electric screw press also has the advantages of simple operation and easy maintenance. Compared with the traditional molding equipment, the electric screw press greatly reduces the operation difficulty and labor intensity, and improves the production efficiency and product quality. At the same time, because of its compact structure and small footprint, it also saves production costs and site resources for enterprises.

In summary, electric screw presses play an important role in refractory production and can significantly optimize product quality. Through the actual production cases, it can be seen that the use of electric screw press for molding production can improve the density and performance of refractory products, reduce the difficulty of operation and labor intensity, and create greater economic and social benefits for enterprises. In the future, with the continuous innovation of electric screw press technology and the expansion of application fields, its position in the refractory industry will be more important.