Diversified firebrick production solutions

Author: haloong Time: 2023-12-21 11:40:07

With the continuous development of the industrial field and the continuous progress of technology, firebrick as an important industrial material, its demand is also increasing. In order to meet the needs of different fields and different application scenarios, the production of refractory bricks needs to have diversified and personalized characteristics. This paper will introduce the production solutions of diversified refractory bricks through actual production cases.

1. Case background

In order to meet the needs of different customers, a firebrick manufacturer has launched a variety of firebrick production solutions. According to the specific requirements of customers, they can produce firebricks with different specifications and different properties by adjusting raw material formula, molding process, firing system and other parameters.

Second, diversified firebrick production solutions

Diversification of raw material formulation

In order to meet the needs of different customers, the company uses a variety of raw material formulations. According to the specific requirements of customers, they choose the right raw material formula to ensure the performance and stability of firebricks. At the same time, they are constantly developing new raw material formulations to adapt to changing market demands.

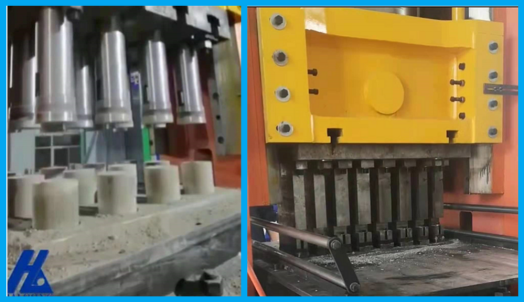

Diversification of molding process

Molding process is one of the key links of refractory brick production. The company adopts a variety of molding processes according to different raw material formulations and customer needs. By adjusting the forming pressure, temperature, time and other parameters of the servo electric screw press, they ensure the dimensional accuracy and density of the refractory brick. At the same time, they continue to optimize the molding process to improve production efficiency and product quality.

The firing system is diversified

The firing system is one of the important factors affecting the properties of refractory bricks. The company adopts a variety of firing systems according to different raw material formulations and customer needs. They ensure the performance and stability of refractory bricks by adjusting the firing temperature, time, atmosphere and other parameters. At the same time, they also continuously optimize the firing system to improve production efficiency and product quality.

3. Practical production and application

Under the guidance of diversified refractory brick production solutions, the company has successfully produced refractory bricks of various specifications and various properties. According to the specific requirements of customers, they customized firebricks with different specifications and different performance. These refractory bricks are widely used in metallurgy, ceramics, glass, chemical and other fields, and have been praised by customers.

Iv. Conclusion

Diversified firebrick production solutions are necessary to meet the needs of different customers. Through the diversification of raw material formula, the diversification of servo electric screw press forming process and the diversification of firing system, enterprises can produce a variety of specifications, a variety of performance of refractory bricks to meet the needs of different fields and different application scenarios. At the same time, enterprises also need to continuously develop new raw material formulations and optimize production processes to adapt to changing market demands and technological advances