How to ensure equipment safety and employee safety during the molding process of shaped brick?

Author: haloong Time: 2024-12-12 17:12:38

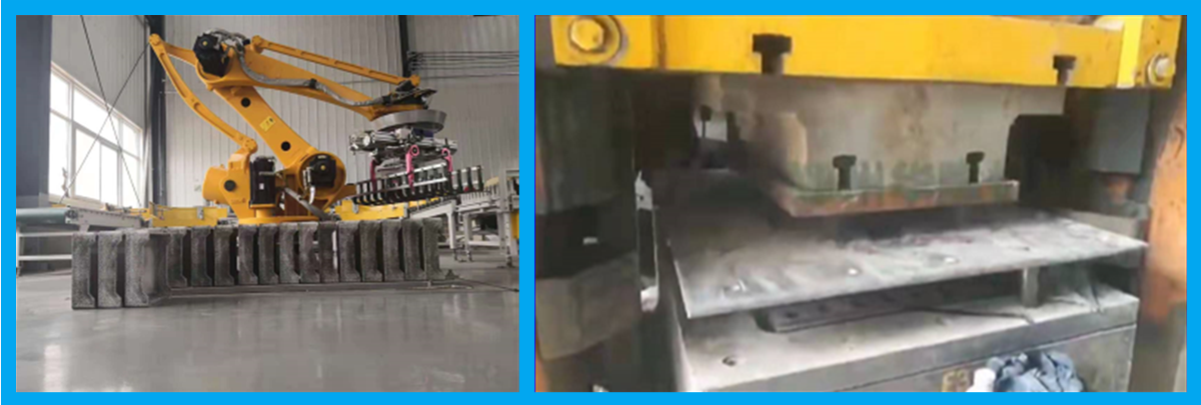

In the forming process of shaped brick, the electric screw press is an important forming equipment, and its safety and stability are crucial to the safety of equipment and employees. Here are some actual production scenarios that illustrate how the servo electric screw press ensures equipment safety and employee safety during shaped brick forming:

Case 1: Equipment security protection

An electric screw press was used in the production of shaped brick in a refractory production enterprise. In order to ensure the safety of equipment, the company has taken the following measures:

Choose the electric screw press with perfect safety functions, such as overload protection, stroke limit, overvoltage protection, overcurrent protection and other functions.

Carry out a comprehensive safety check before operation of the equipment, including the transmission system, hydraulic system, electrical system, etc., to ensure that the equipment is in good working condition.

Formulate strict equipment operation procedures and safety management system, conduct equipment safety training for employees, and ensure that employees understand the safe operation methods of equipment and emergency handling measures.

Regular maintenance and maintenance of the equipment, timely detection and resolution of potential safety hazards.

Through the above measures, the company successfully ensured the equipment safety of the electric screw press and reduced the occurrence of equipment failures and accidents.

Case 2: Employee safety protection

In addition to the safety measures of the equipment itself, the safety of employees is also important. Here is another practical production case that illustrates how to ensure employee safety during the molding process of shaped bricks:

On the special-shaped brick forming production line of a refractory production company, employees need to strictly comply with the following safety regulations when operating the electric screw press machine:

Employees must go through professional safety training to understand the safe operation procedures of the electric screw press and the handling measures in emergency situations. When operating the equipment, employees must wear appropriate labor protection products, such as safety helmets, protective glasses, gloves, etc.

Before entering the production line, employees must understand the safety warning labels and safety operation procedures on site to ensure compliance with relevant regulations. The scene must be equipped with appropriate first aid equipment and personnel, in order to deal with the accident in time.

Enterprises should regularly organize employees to conduct safety drills and simulation drills to improve their emergency handling ability and self-protection ability. Through the above measures, the employees of the company have been effectively protected when operating the electric screw press, reducing the occurrence of industrial accidents.

In summary, in the molding process of shaped brick, the servo electric screw press can ensure equipment safety and employee safety by taking appropriate safety measures and regulations. The enterprise shall strengthen the safety management of equipment and the training and education of employees, improve the safety awareness and operation skills of employees, and ensure the safe and stable operation of the production line.