Help waste powder to turn waste into treasure

Author: haloong Time: 2023-12-06 15:45:35

With the release in June 2022 of the "Implementation Plan for Carbon Reduction Synergies" jointly issued by the Ministry of Ecology and Environment and the National Development and Reform Commission, comprehensive utilization of resources has become an urgent task for refractory enterprises. In this context, the servo electric screw press, with its excellent performance and innovative technology, is helping enterprises to transform waste powder into treasure.

First, tailings molding - increase the use of waste into treasure

Mining enterprises are the main body of resistant material enterprises, the treatment and utilization of tailings is not only related to the economic benefits of mines, but also an important measure to save resources and improve the environment. The traditional tailings treatment method often causes pressure on the environment, and the introduction of servo electric screw press provides a new solution for tailings molding.

With the high precision and high efficiency of the servo electric screw press, the tailings can be pressed into products of various shapes and sizes, such as bricks, roadbed materials, etc. This not only extends the utilization cycle of tailings, improves the utilization rate of resources, but also reduces the dependence on primary resources, and achieves a win-win situation of economic and environmental benefits.

Second, steel slag molding - give full play to advantages and create value

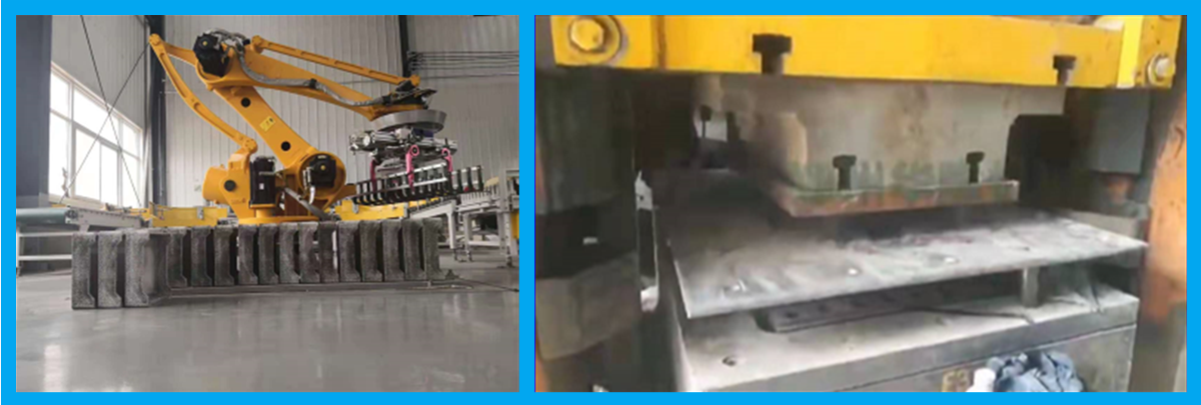

Iron and steel enterprises, as the main upstream supply enterprises of resistant material industry, produce a large amount of steel slag every year. The traditional treatment of steel slag is mainly stacking and landfilling, which not only occupies a lot of land, but also may cause environmental pollution. However, some forward-looking enterprises have begun to use electric screw presses to turn steel slag into waste.

By mixing the fine steel slag with fly ash, and then using the high precision control of the servo electric screw press for pressure molding, the steel slag brick, sidewalk brick and other products can be produced. This not only solves the problem of steel slag stacking, but also improves the utilization value of steel slag and fly ash and other wastes, creating a new economic growth point for iron and steel enterprises.

Third, box soil molding - improve the quality, to achieve recycling

Saggar is an important raw material in ceramic industry, and its quality directly affects the quality of ceramic products. The traditional saggar forming method is often inefficient and the yield is not satisfactory. However, the introduction of the servo electric screw press has brought revolutionary changes to the box molding.

With the high precision control and high efficiency of the servo electric screw press, the saggar can be formed quickly and accurately. This not only increases the loading capacity, reduces the bonding problem of the product, but also improves the yield. At the same time, the formed saggar also has certain thermal conductivity and thermal stability, which ensures the quality of ceramic products.