Analysis of automatic production line for refractory materials

Author: haloong Time: 2024-12-16 16:11:45

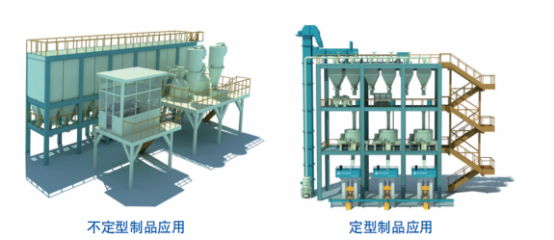

With the vigorous development of the refractory industry and the growing market demand, many customers at home and abroad are planning to build new automatic production lines for refractory bricks. However, due to the lack of in-depth understanding of the industry, many people are unfamiliar with the automatic production and manufacturing process of refractory bricks. By analyzing the fire brick automatic production line step by step, the whole process becomes more easy to understand.

I. Overview of the production line process

The process of the automatic refractory brick production line exhibited by Hualong includes the steps of raw material lifting, automatic batching, mixing, weighing, molding, testing and palletizing. In this series of processes, the servo electric screw press plays a crucial role, mainly responsible for the pressing of the brick.

Second, core equipment: servo electric screw press

As the core equipment in the production line, the servo electric screw press provides a strong guarantee for the production of refractory bricks with its unique advantages. The press adopts advanced servo control system, which can accurately control the pressing force and speed to ensure that the quality and density of the brick meet the requirements. At the same time, the design of the spiral structure makes the pressing process more uniform, and effectively avoids the problem of cracking or deformation of the refractory brick.

Third, the advantages of automated production lines

By introducing advanced equipment such as servo electric screw presses, Hualong has successfully created an efficient, energy-saving and environmentally friendly automatic refractory production line. This line has the following advantages:

Improve production efficiency: Automated production lines can run continuously and stably, greatly reducing manual operations and improving production efficiency. In addition, by optimizing equipment configuration and production process, the production cycle can be further shortened and production costs reduced.

Ensure product quality: The introduction of advanced equipment such as servo electric screw press makes the parameters in the production process accurately controlled. With the online testing system, it can find and eliminate unqualified products in time, so as to ensure that every firebrick delivered by the factory meets the quality requirements.

Reduce energy consumption and emissions: The automated production line adopts advanced energy-saving technology and environmental protection equipment, such as servo control system can adjust the equipment running power according to the actual production needs, reduce energy consumption; At the same time, the waste and exhaust gas generated in the production process have also been effectively treated and utilized, reducing the impact on the environment.

Improve the competitiveness of enterprises: Through the construction of automated production lines, enterprises can not only improve product quality and production efficiency, but also reduce production costs and energy consumption, thereby enhancing the competitiveness of domestic and foreign markets. In addition, the introduction of automated production lines can also enhance the brand image and visibility of enterprises, attracting more customers and partners.

With the continuous progress of science and technology and the continuous growth of market demand, the automatic production line of refractory materials is expected to be further upgraded and improved. For example, more precise control of production processes through the introduction of more advanced control systems and sensor technology; Develop new materials and processes to improve the performance and application range of refractory bricks; Promote the application of industrial robots and artificial intelligence technology in production lines to achieve a higher degree of automation and intelligence.

In short, the construction of automatic refractory production line with servo electric screw press as the main equipment is the inevitable trend of the development of refractory industry. Through the introduction of advanced equipment and technology, optimization of production processes and management models and other measures, resistant material enterprises can not only improve product quality and production efficiency, reduce production costs and energy consumption, enhance market competitiveness, but also contribute to the sustainable development and innovation of the entire industry.