A new chapter in quiet production of magnesium carbon brick factory

Author: haloong Time: 2024-05-13 18:19:02

In an industrialized city in China, there is a magnesia-carbon brick factory. In the past, its production activities have been accompanied by huge noise, which has brought great troubles to the lives of surrounding residents. In order to solve this problem, the factory owner decided to introduce a new equipment - 630T fully sealed hydrostatic structure servo electric screw press.

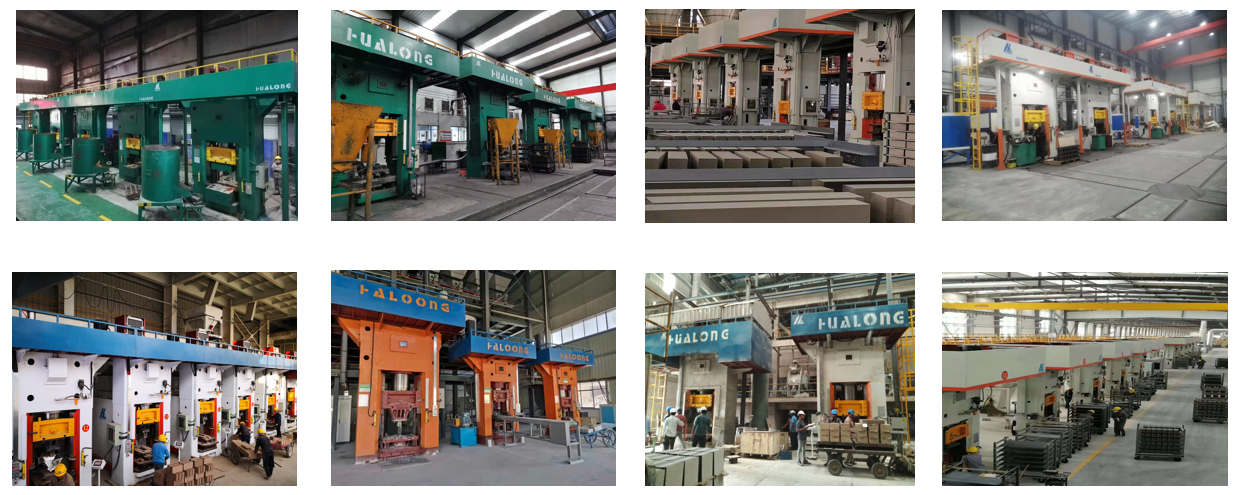

This equipment comes from Zhengzhou Hualong Machinery, which uses a fully sealed static pressure structure to completely solve the problem of loud noise and disturbing the people of traditional forging equipment. At the same time, it has played a huge advantage in the forming process of magnesia-carbon bricks.

After the introduction of the new equipment, the production line of the magnesium-carbon brick plant began to change. Production, which used to be noisy, has become much quieter with the help of new equipment. Surrounding residents no longer have to endure the deafening noise, and the quality of life has been greatly improved.

In the forming process of magnesium-carbon bricks, the 630T fully sealed hydrostatic structure of the servo electric screw press shows high accuracy and stability. Due to the fully sealed structure, the equipment can effectively prevent noise leakage during the production process, but also ensure stability and accuracy during the molding process.

In addition, the control accuracy of this device is very high. With advanced servo electric technology, it can achieve precise force and speed control, thus ensuring the accuracy of every production link. This precise control can not only improve product quality, but also greatly reduce the loss of molds, and save a lot of costs for manufacturers.

In terms of production efficiency, the 630T fully sealed hydrostatic structure of the servo electric screw press also performs very well. Due to its high-precision control and efficient performance, the production efficiency of the equipment is greatly improved, thus increasing the production capacity of the entire magnesium-carbon brick plant.

This case tells us that the 630T servo-electric screw press with fully sealed hydrostatic structure has significant advantages in the forming process of magnesium-carbon bricks. By introducing this device, the magnesia carbon brick factory not only solved the problem of noise nuisance, but also improved production efficiency and injected new vitality into their future development.