Servo electric screw press: Revolutionary and convenient operation for refractory brick production

Author: haloong Time: 2024-05-21 17:29:48

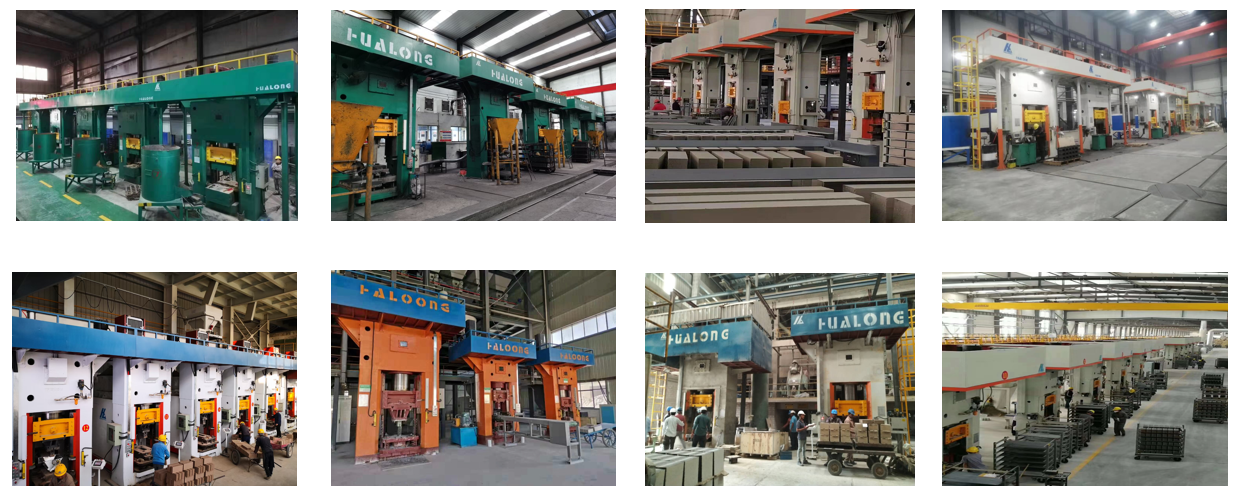

With the rapid development of science and technology, the electric screw press is increasingly widely used in the field of refractory brick production. Especially the servo electric screw press, its convenience and efficiency of operation has brought revolutionary changes to the production of refractory bricks. Compared with the traditional friction press, the servo electric screw press is driven by its flexible and controllable servo motor, which realizes the automation and intelligence of firebrick production.

In the past, the old friction press required a lot of manpower in the production of refractory bricks. Workers need to manually load, move bricks, and operate machines for pressing. However, this mode of production is not only inefficient, but also the labor intensity of workers and the working environment is bad. With the introduction of the servo electric screw press, all this has been fundamentally changed.

Servo electric screw presses are driven by advanced servo motors to achieve precise control of pressure, speed and position. This makes the operation of the machine extremely convenient. Workers no longer need to manually load and move bricks, but can achieve continuous refractory brick production through automated production lines. The whole production process realizes unmanned operation, which greatly improves the production efficiency.

The perfect combination of servo electric screw press and firebrick automatic production line makes the production of firebrick workshop fast, efficient and humane. Each link in the production line can achieve accurate coordination, avoiding errors and delays in manual operation. This highly automated production method not only reduces the labor intensity of workers, but also improves the working environment and provides more comfortable working conditions for workers.

In addition, the energy-saving and environmental protection characteristics of the servo electric screw press have also been fully reflected. Due to its high efficiency of energy utilization and low noise and vibration operation characteristics, the energy consumption and environmental impact of the firebrick workshop have been effectively controlled. This not only conforms to the green concept of modern industry, but also brings significant economic benefits to the enterprise.

In summary, the application of the servo electric screw press in the production of refractory bricks has brought revolutionary changes. Its flexible and controllable servo motor drive, efficient and convenient operation mode and energy-saving and environmental protection characteristics make the production of refractory bricks more efficient, humanized and in line with the development trend of modern industry. In the future, we have reason to believe that the servo electric screw press will continue to lead the innovation and development in the field of refractory brick production, bringing more convenience and benefits to industrial production.