The advantages of one-click powder forming press in shaped brick forming

Author: haloong Time: 2023-11-16 15:15:53

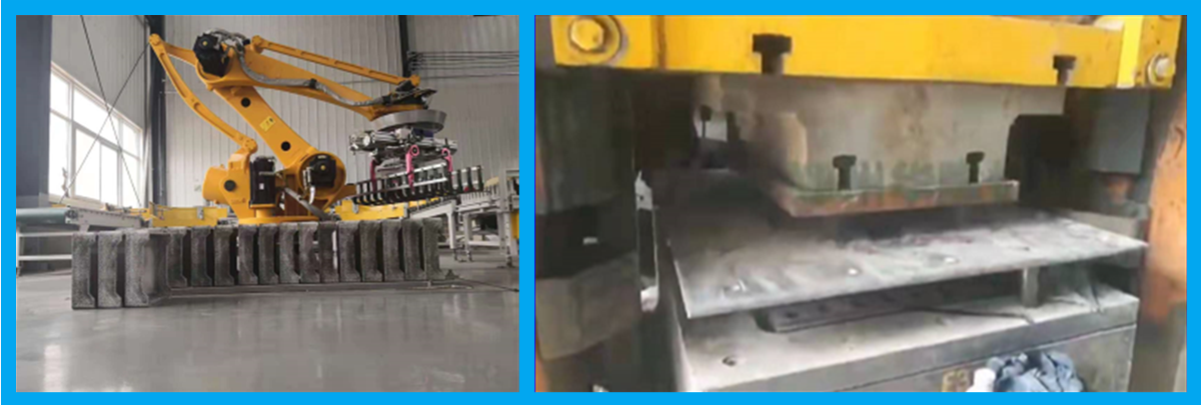

In the construction industry, shaped bricks are widely used because of their unique shape and excellent performance. However, the traditional special-shaped brick production mode has some problems, such as low efficiency, high energy consumption and unstable product quality. In recent years, the emergence of one-click powder molding press has brought revolutionary changes to the production of special-shaped bricks. In this paper, the advantages of one-button operation powder forming press in special-shaped brick forming will be expounded through case study.

First, efficient production

The one-click powder forming press uses advanced automation technology, which can convert powder into finished product in a short time, greatly improving production efficiency. At the same time, the equipment has the ability of continuous production, which can achieve large-scale production under the premise of ensuring product quality.

Actual case: A construction company uses a one-button operation powder forming press to produce special-shaped bricks, compared with the traditional production method, the production efficiency is increased by 30%, and the production cycle is greatly shortened. At the same time, due to the good stability of the equipment, the rejection rate has been effectively controlled.

2. Energy saving and consumption reduction

The one-button operated powder forming press uses an advanced electric servo system, which has higher energy conversion efficiency and lower energy consumption compared to traditional hydraulic systems. In addition, the device also has an intelligent energy management function, which can automatically adjust energy consumption according to production needs, further reducing production costs.

Actual case: A brick factory uses a one-button operation powder forming press to produce special-shaped bricks, which can save more than 30% of electric energy per year compared with the traditional production method, saving a lot of energy costs for enterprises.

Third, stable product quality

The one-click powder molding press adopts high-precision mold and precise control system, which can precisely control various parameters in the molding process, so as to produce more stable quality special-shaped brick products. In addition, the device also has automatic detection and adjustment functions, which can adjust parameters in time according to product feedback, ensuring that product quality is always in the best condition.

Actual case: A building materials company uses a one-click powder molding press to produce special-shaped bricks, and the product quality has been significantly improved. In customer feedback, product consistency and stability are significantly better than those of traditional production methods.

Fourth, reduce labor costs

The one-click powder forming press has the ability to automate and continuously produce, which can reduce manual intervention and operation difficulty. At the same time, the equipment is also equipped with intelligent fault diagnosis and early warning system, which can find and solve problems in time, reduce the equipment failure rate, and further reduce the manual maintenance cost.

Actual case: A special-shaped brick production enterprise uses a one-button operation powder forming press for production, and the labor cost is reduced by 20%. In addition, due to the low failure rate of the equipment, the maintenance cost has been effectively controlled.

Fifth, adapt to diverse needs

The one-button operation powder forming press is suitable for the production of various shaped bricks, which can meet the customized needs of different customers for different products. In addition, the device also has a flexible adjustment function, which can quickly adjust product specifications and types according to market demand, and improve the market adaptability of enterprises.

Actual case: A construction company uses a one-click operation powder forming press to produce a variety of specifications and types of special-shaped bricks to meet the needs of different customers. Because the device also has a rapid adjustment function, the company is able to respond quickly to market changes and expand into new business areas.

In summary, the one-button powder forming press has the advantages of high efficiency, energy saving and consumption reduction, stable product quality, reducing labor costs and adapting to diversified needs in special-shaped brick forming. Through the analysis of practical cases, we can see the importance and application prospect of this equipment in the production of special-shaped bricks. For the pursuit of efficient, high-quality, low-cost production enterprises, the choice of one-click operation powder molding press is a wise choice. This will help improve the competitiveness of enterprises and achieve the Sustainable Development Goals.