The selection of powder forming press brings advantages to tailings forming enterprises

Author: haloong Time: 2024-06-06 17:47:52

In the production process of tailings molding enterprises, energy consumption is an important consideration. In order to reduce costs and improve efficiency, more and more enterprises have begun to choose powder forming presses as the main production equipment.

First, the advantages of powder forming press

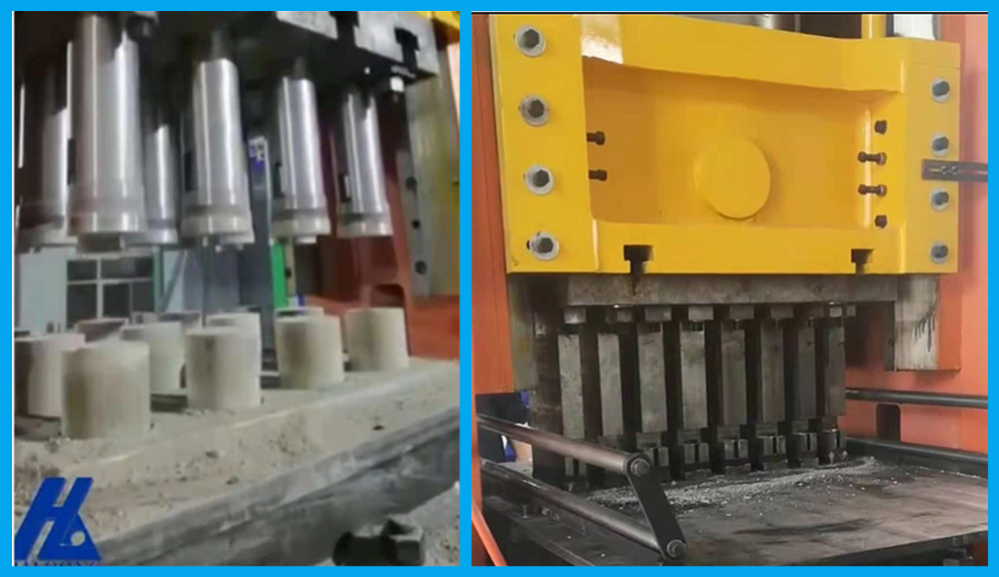

Powder molding press is a new type of tailings molding equipment, with the following advantages:

Energy saving and environmental protection: The powder molding press adopts advanced molding technology, which can realize the molding of tailings with low energy consumption. Compared with the traditional tailings molding method, it can greatly reduce energy consumption and environmental pollution.

High production efficiency: The powder molding press has an efficient production capacity and can quickly convert tailings into finished products. This helps to improve the production efficiency of enterprises and meet the market demand.

Good product quality: The powder molding press can precisely control the parameters of the molding, so as to produce more stable quality tailings products. This helps to improve the product quality and economic benefits of enterprises.

Low maintenance cost: powder molding press has simple structure, easy maintenance and low failure rate. This saves companies a lot of repair and maintenance costs.

2. Actual production cases

In order to reduce energy consumption and improve production efficiency, a powder molding press was introduced in a tailings molding enterprise. Through the actual production verification, the equipment has shown good performance. The following is a detailed analysis of the case:

Reduce energy consumption: The powder forming press saves a lot of energy during the production process compared to the traditional tailings forming method. It is estimated that it can save about 30% of energy costs for enterprises every year.

Improve production efficiency: The rapid response and efficient production capacity of the equipment makes the production efficiency of the enterprise has been significantly improved. The production cycle is shortened by 20%, which greatly improves the production efficiency of the enterprise.

Stable product quality: The precise control and stability of the powder forming press make the quality of the produced tailings more stable. The rejection rate has been reduced by 15%, and the product quality and economic benefit of the enterprise have been improved.

Reduce maintenance costs: Because the maintenance cost of the equipment is low, the maintenance cost of the enterprise is also effectively controlled. It can save about 20% of maintenance costs for enterprises every year.

Through the analysis of the above actual production cases, we can see that the powder molding press has brought significant advantages to the tailings molding enterprises in terms of reducing energy consumption. It not only reduces the energy consumption and maintenance costs of enterprises, but also improves the production efficiency and product quality of enterprises. Therefore, for tailings molding enterprises, the choice of powder molding press is a wise investment decision, which helps enterprises to maintain a leading position in the fierce market competition and achieve sustainable development.