Characteristics and advantages of iron powder forming press die

Author: haloong Time: 2023-11-16 10:10:19

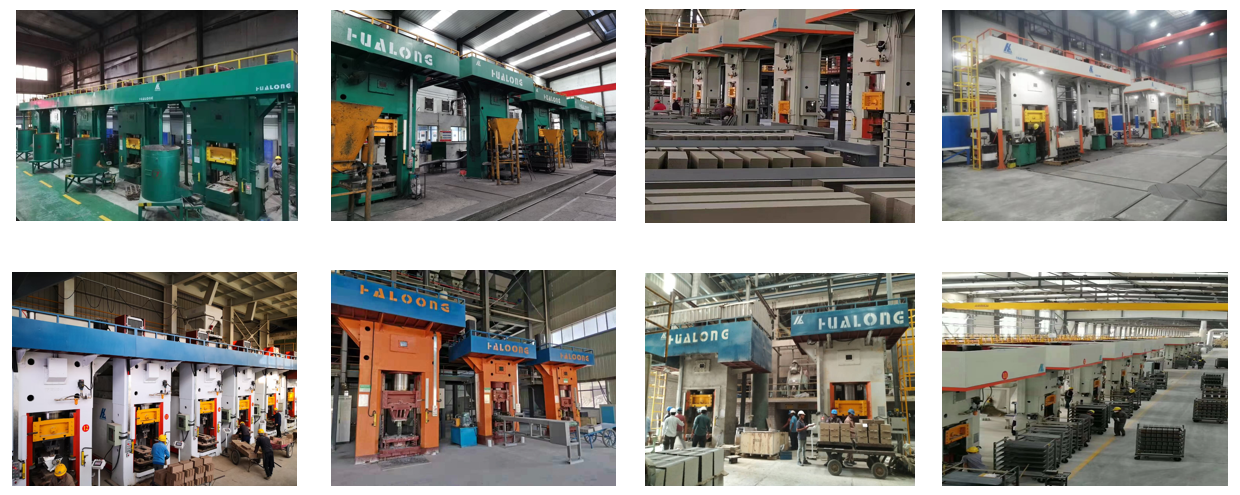

In today's manufacturing industry, the choice of powder forming press die has a crucial impact on the quality and efficiency of the production process. Taking iron powder as an example, it has unique physical and chemical properties, so a special powder molding press die is required to carry out the molding operation. In this paper, the characteristics and advantages of iron powder molding press die are introduced in detail, and its application is illustrated by practical production cases.

First, the characteristics of iron powder molding press die

Iron powder molding press mould has high strength, high wear resistance and corrosion resistance. Due to the high hardness of iron powder, the mold needs to be able to withstand high pressure and high temperature. In addition, the iron powder molding press mold also needs to have good thermal stability and high thermal conductivity to ensure temperature control and uniform transfer during the molding process.

Two, the advantages of iron powder molding press mold

Iron powder molding press mold can achieve high precision, high density and high consistency molding. Its advantages are mainly reflected in the following aspects:

Improve production efficiency: Through the characteristics of rapid prototyping, it can shorten the production cycle and improve production efficiency.

Cost reduction: Due to the use of high pressure molding, iron powder molding press molds can reduce the use of raw materials and reduce production costs.

Optimize product performance: Through high density and high consistency molding, the mechanical and electrical properties of the product can be improved.

3. Actual production cases

An automobile factory uses iron powder forming press molds to produce auto parts. By using the mold, the factory achieved the following points:

Improve production efficiency: After the use of iron powder molding press mold, the production cycle is shortened by 20% and the production efficiency is improved.

Cost reduction: By reducing the use of raw materials, the plant has succeeded in reducing production costs.

Optimized product performance: The mechanical and electrical properties of the parts are significantly improved by the use of high density and high consistency molding.

In short, the iron powder molding press mold has unique characteristics and advantages, and can meet the various needs of the actual production process. By using the right mold, companies can improve production efficiency, reduce costs and optimize product performance. In the highly competitive manufacturing industry, choosing the right powder forming press mold will be one of the keys to the success of the enterprise.