Application of 1600T powder forming press in the production of graphite products

Author: haloong Time: 2024-06-17 18:07:17

In the production field of powder products, 1600T powder forming press is widely used in the pressing of various powder materials with its high pressure and high precision. In recent years, with the increasing popularity of graphite products, 1600T powder molding press has also played an important role in the production of graphite products.

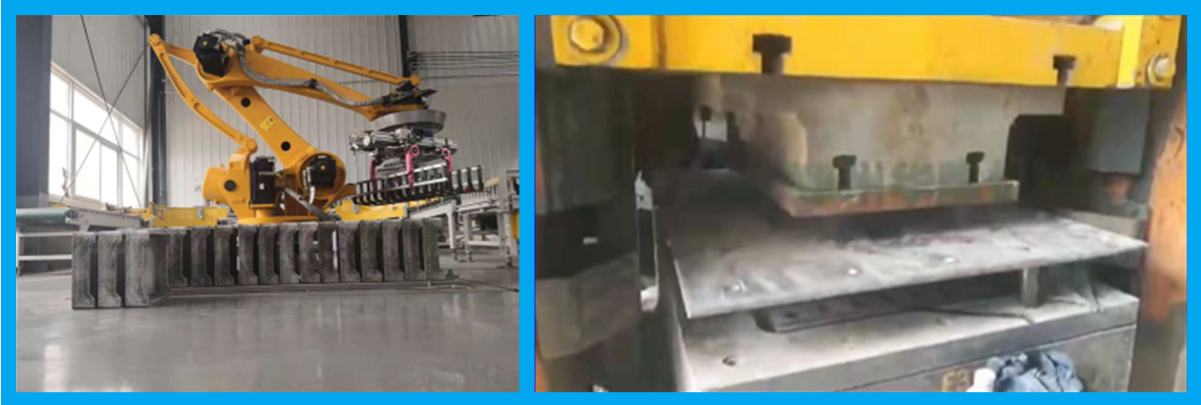

Case introduction: A graphite products enterprise is a professional manufacturer of various graphite products, the products cover the graphite electrode, graphite mold and other fields. In order to improve production efficiency and product quality, the company introduced a 1600T powder molding press, which is mainly used for the pressing of graphite products.

Production process: In the production process of graphite products, the graphite powder is first mixed with an appropriate amount of binder to form a plastic billet. The billet is then placed into the mold of the 1600T powder forming press, and the graphite product of the desired shape and size is formed through high pressure pressing.

Finally, the final graphite product is obtained by subsequent processing such as demudding and sintering.

Advantages: 1600T powder forming press has the following advantages in the production of graphite products:

High pressure output: The 1600T powder molding pressure function provides high pressure pressing, which helps to improve the density and strength of graphite products and optimize the physical properties of products.

Precise control: The equipment has accurate pressure and shape control capabilities, which can ensure that the size and shape of each graphite product meet the design requirements, and improve the product pass rate.

High efficiency and energy saving: 1600T powder forming press adopts advanced energy saving technology, which can effectively reduce energy consumption and save costs for enterprises.

Wide range of application: the equipment can be applied to different types of graphite powder materials to meet the needs of different fields.

Improve production efficiency: Through automation and intelligent operation, 1600T powder forming press can greatly improve production efficiency and reduce labor costs.

Through the introduction of 1600T powder molding press, the graphite products company successfully achieved efficient and high-quality graphite products production. The density and strength of the product have been significantly improved, and the production cost has been effectively controlled. This fully proves the importance and application value of 1600T powder forming press in the production of graphite products.

With the continuous progress of science and technology and the development of manufacturing industry, we have reason to believe that 1600T powder forming press will be widely used in more fields in the future, providing more reliable technical support for the development of various industries.