630T powder forming press: Variety of pressing products

Author: haloong Time: 2024-06-14 14:07:06

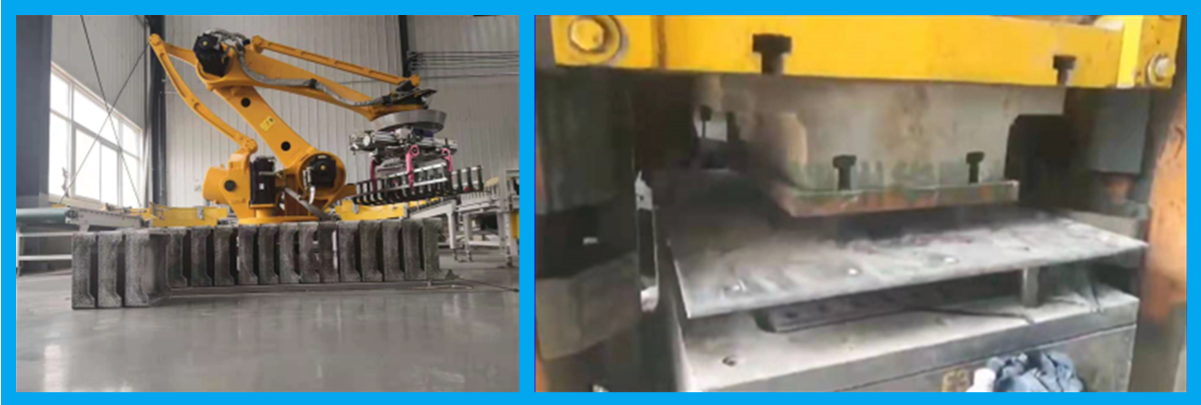

In today's manufacturing industry, the 630T powder forming press, as an efficient, flexible and versatile equipment, is widely used in a variety of different types of powder product pressing. By precisely controlling the pressing process, the machine is able to produce powder products with excellent performance and high quality to meet the needs of different fields. This paper will discuss the advantages and characteristics of 630T powder forming press in different application fields through practical cases.

Case 1: Production of ceramic powder products

A ceramic products enterprise uses 630T powder forming press for production, mainly producing ceramic powder products such as ceramic tools, ceramic parts and so on. During the pressing process, the high pressure output and precise control of the equipment ensure the density and strength of the ceramic powder, while maintaining consistent pressure and shape control, resulting in higher performance and consistency of the ceramic powder products produced. By optimizing the process parameters, the company successfully improved the product quality and production efficiency, and won the recognition of the market.

Case 2: Cemented carbide production

A cemented carbide manufacturing enterprise uses 630T powder forming press for production, mainly producing cemented carbide products such as cemented carbide cutting tools, cemented carbide parts, etc. Carbide with high strength, high hardness, high temperature resistance and other characteristics, is widely used in machinery, aviation, energy and other fields. During the pressing process, the precise control and high pressure output of the equipment ensure the density and strength of the cemented carbide powder, while maintaining consistent pressure and shape control, so that the produced cemented carbide products have higher performance and consistency. By optimizing process parameters, the company successfully reduced costs and improved market competitiveness.

Case 3: Production of graphite products

A graphite products enterprise uses 630T powder molding press for production, mainly producing graphite products such as graphite electrodes, graphite molds, etc. As a non-metallic material, graphite has the characteristics of high conductivity, high corrosion resistance, etc., and is widely used in electronics, chemical industry and other fields. During the pressing process, the precise control and high pressure output of the equipment ensure the density and strength of the graphite powder, while maintaining consistent pressure and shape control, resulting in higher performance and consistency of the produced graphite products. By optimizing process parameters, the company successfully improved product quality and production efficiency, and won the trust of customers.

The 630T powder forming press has a very wide range of applications and can be used for pressing different types of powder products. Whether in the production of ceramics, cemented carbide or graphite products, the equipment can provide excellent pressing results and improve product quality and performance. At the same time, the flexibility and efficiency of the equipment also provide enterprises with more production options and greater market competitiveness. With the continuous progress of science and technology and the development of manufacturing, we have reason to believe that 630T powder molding press will play a more important role in the production of powder products in the future.