The role of powder forming press in the press forming of salt brick of cattle and sheep and the actual production case

Author: haloong Time: 2024-10-22 17:10:00

The powder forming press plays a vital role in the pressing and forming of salt bricks of cattle and sheep. Salt brick is an important feed additive, which can supplement the minerals and nutrients required by cattle and sheep to improve their health and production performance. The high pressure and high precision of the powder forming press make the salt brick production process more efficient and stable.

First, the role of powder forming press in the pressing and forming of salt bricks of cattle and sheep

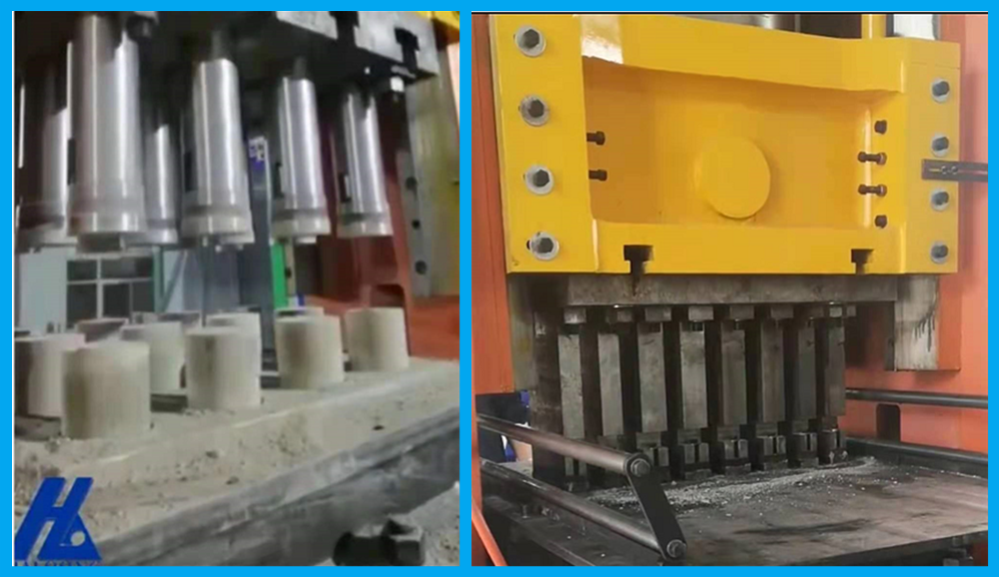

Efficient pressing: The powder forming press uses high pressure and high frequency of impact force to press powdered raw materials into complex shapes. This efficient pressing method greatly shortens the production cycle of salt brick and improves the production efficiency.

Precise control: The powder forming press has precise pressure and position control to ensure the shape and dimensional accuracy of the salt brick. At the same time, by adjusting the pressing parameters, different specifications and shapes of salt bricks can be produced to meet the needs of different users.

Improve product quality: The high pressure pressing process of the powder forming press can reduce the pores and defects in the raw material and improve the density and strength of the salt brick. In addition, through accurate mold design and pressing process control, the surface of the salt brick can be ensured to be smooth and flat, and the appearance quality of the product can be improved.

Reduce production costs: Powder molding press has a high degree of automation, which can reduce manual operation and intervention, and reduce labor costs. At the same time, efficient pressing and precise control can reduce raw material waste and scrap rates, thereby reducing production costs.

2. Actual production cases

In order to produce high quality salt bricks for cattle and sheep, a feed processing enterprise introduced a powder forming press to produce. The following is the actual production case of the enterprise:

Salt brick production process: The company first mixes the required minerals and additives into powdered raw materials in accordance with a certain proportion, and then puts it into the mold of the powder forming press, and shapes it into regular salt bricks through the high-pressure pressing process. After the pressing is completed, the salt brick is subjected to subsequent treatment, such as cooling, packaging, etc.

Production efficiency and product quality: With the use of a powder forming press, the production efficiency of the salt brick of the enterprise has been significantly improved. At the same time, due to the precise mold design and pressing process control, the salt brick has high dimensional accuracy, smooth surface and uniform density, which improves the quality and stability of the product.

Cost control: By using powder forming presses, the company reduces manual operation and intervention, reducing labor costs. At the same time, efficient pressing and precise control reduce raw material waste and scrap rates, reducing production costs. In addition, high-quality salt brick products also improve the market competitiveness of enterprises.

In summary, the powder forming press plays an important role in the pressing and forming of salt bricks of cattle and sheep. Its advantages of efficient pressing, precise control, improving product quality and reducing production costs make the production process of salt brick more efficient, stable and reliable. For feed processing enterprises, the introduction of powder molding press is one of the important ways to improve production efficiency and product quality.