Powder forming press: multi-function pressing specialist

Author: haloong Time: 2024-12-18 17:07:20

With the continuous progress of science and technology, powder molding presses play an important role in many industries and become indispensable equipment for manufacturing various products. The versatility of powder forming press makes it widely used in different industries, this paper will introduce the versatility and application of powder forming press through some specific production cases.

1. Metal manufacturing: mass production of auto parts

Powder forming presses are widely used in the metal manufacturing industry, one of the most representative application cases is the mass production of automotive parts. The automotive manufacturing industry has very high dimensional accuracy and performance requirements for parts, and powder forming presses can produce high-quality, high-precision metal products to meet these requirements.

For example, in the automotive industry, powder forming presses can be used to produce complex parts such as cylinder blocks and heads for automotive engines. By placing metal powder into the mold and applying high pressure, a cylinder block or head with complex shape can be formed at one time, greatly improving production efficiency and reducing production costs. At the same time, due to the high pressing accuracy of the powder molding press, the dimensional accuracy and consistency of the parts can be ensured, and the performance and reliability of the car can be improved.

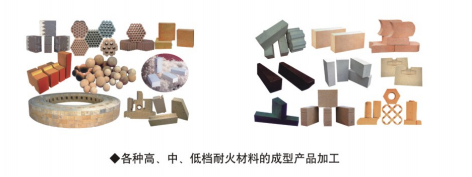

Second, ceramic manufacturing: efficient preparation of high-performance ceramic products

Powder forming presses are also widely used in ceramic manufacturing. Ceramic products have good water absorption, wear resistance, high temperature resistance and other excellent properties, widely used, such as building materials, daily ceramics and so on. Through the use of powder forming press, it is possible to achieve accurate pressing of ceramic powder, so as to obtain ceramic products with complex shapes.

For example, in the production of high-performance ceramic tools, ceramic powder can be put into the mold, and the shape and size of the tool can be formed at one time by pressing the powder forming press. This production method can not only improve production efficiency, but also obtain ceramic tools with excellent performance to meet people's requirements for high hardness, high wear resistance and high heat resistance of the tool.

Third, powder molding press: cattle and sheep salt brick pressing molding

Powder forming press is also known as powder oil press, powder forming press. It is mainly used in the molding process of powder, particle, fiber and other materials. In the food industry, powder forming presses can be used to produce a variety of solid drinks and condiments.

For example, in the production of salt bricks of cattle and sheep, salt and other condiments can be ground into powder and put into a mold, and the salt bricks of cattle and sheep can be obtained by pressing and forming the powder forming press. This production method can not only improve the production efficiency, but also get a good taste and nutritional value of cattle and sheep salt brick products.

With the continuous progress of science and technology and the support of national policies, it is believed that the application prospect of powder molding press will be broader. In the future, with the continuous development of intelligent manufacturing technology, powder molding presses will be more intelligent and automated. Through the introduction of robots and automated control systems, the production process can be automated and optimized.