The important role of graphite powder forming press in battery manufacturing

Author: haloong Time: 2023-11-09 10:50:26

As the market for electric vehicles and renewable energy continues to expand, the battery manufacturing industry is experiencing unprecedented growth. Graphite is an excellent battery material, and its powder forming press is playing an increasingly important role in battery manufacturing.

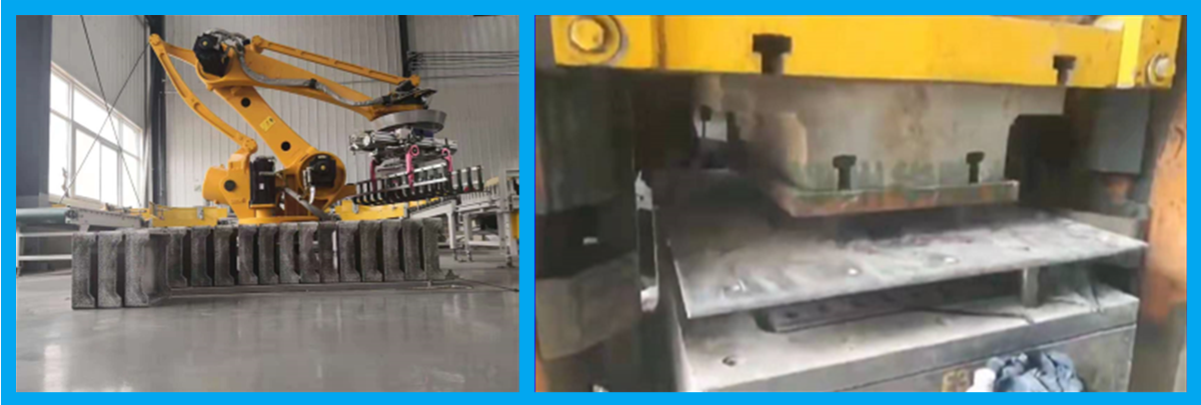

Graphite powder molding press is an advanced manufacturing equipment, mainly used to press graphite powder into various shapes and specifications of products. By using graphite powder forming presses, production efficiency and product quality can be significantly improved, while reducing production costs.

In the battery manufacturing, the application advantages of graphite powder molding press are mainly reflected in the following aspects:

Improve production efficiency: graphite powder molding press can achieve automated production and improve production efficiency. At the same time, because the pressing process of graphite powder can be completed in a short time, the production cycle can be greatly shortened.

Guarantee product quality: The graphite powder forming press can improve product quality by precisely controlling the pressing process to ensure the consistency of product size, shape and performance.

Reduce production costs: The use of graphite powder molding press can reduce production costs. First, automated production can reduce labor costs; Secondly, efficient production can reduce energy consumption; Finally, high-quality products can reduce the scrap rate, thus reducing production costs.

In actual production, one of the application cases of graphite powder molding presses is the manufacturing of negative electrode materials for lithium-ion batteries. Lithium-ion batteries are one of the most commonly used battery types, and their negative electrode material is one of the key factors in battery performance. The use of graphite powder molding presses can quickly and efficiently produce high-quality anode materials for lithium-ion batteries, thereby improving the energy density and cycle life of the batteries.

Another application is the positive electrode material for graphene batteries. Graphene is a new type of nanomaterial with excellent electrical conductivity and chemical properties. The use of graphite powder molding press can produce high-quality graphene battery cathode materials with three-dimensional network structure, thereby improving the energy density and charge and discharge performance of the battery.

In short, graphite powder molding presses play an important role in battery manufacturing. By using graphite powder forming presses, production efficiency and product quality can be significantly improved, while reducing production costs. With the continuous expansion of electric vehicles and renewable energy markets, the application prospects of graphite powder molding presses will be broader.