Application scenarios and advantages of screw press in refractory brick production

Author: haloong Time: 2023-10-05 14:16:00

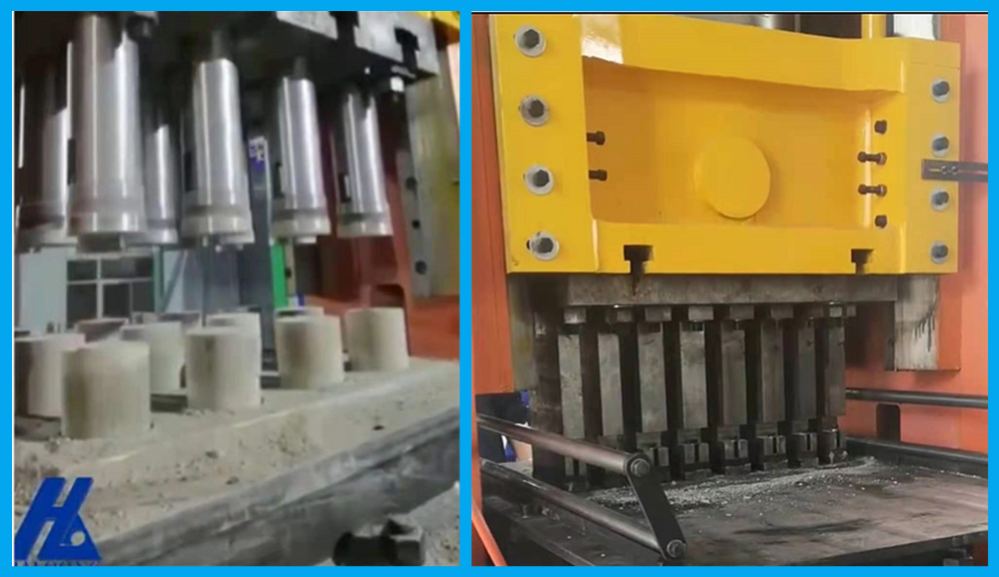

Firebrick is a kind of building material used in high temperature environment, its quality and performance are crucial to ensure industrial production and personal safety. In the production process, the selection of appropriate production equipment is crucial to improve production efficiency and quality. As an advanced production equipment, screw press plays an important role in the production of refractory brick.

The advantages of screw press in refractory brick production are mainly reflected in the following aspects:

High efficiency: Screw press adopts advanced transmission mode and control system, which can achieve high efficiency production. Compared with the traditional manual forging method, the equipment can greatly improve the production efficiency, reduce the production cycle and cost.

High precision: The screw press adopts a high precision and stable transmission mode, which can achieve precise control and optimization. This high precision and stability ensure the quality control in the production process of firebrick and improve the qualified rate of the product. In addition, because the equipment can achieve a variety of different specifications and shapes of firebrick production, can meet the needs of different customers, improve the diversity and competitiveness of products.

Low energy consumption: Screw press adopts advanced electric drive technology and optimized transmission mode, which can greatly reduce energy consumption. Compared with the traditional manual forging method, the equipment can reduce energy waste and environmental pollution. In addition, because the equipment can realize the effective use of resources, it can reduce the exploitation and destruction of natural resources, which is conducive to environmental protection.

High degree of automation: The screw press can automate production, reducing manual intervention and error rate. This automatic production mode can reduce labor costs and reduce the human resources input of enterprises. At the same time, because the equipment is simple to operate and easy to maintain, the training and management cost of the operator can be reduced.

Flexibility and adaptability: The screw press has a large working space and strong processing capacity, which can meet the production needs of various complex shapes and large refractory bricks. At the same time, the equipment also has good flexibility and adaptability, can be quickly adjusted and produced according to the needs of different customers. This flexibility and adaptability makes the device more competitive in the market.

In summary, the screw press has significant advantages and a wide range of application scenarios in the production process of refractory bricks. The equipment can improve production efficiency, improve product quality, reduce labor costs, environmental protection and energy saving, and has the characteristics of flexibility and adaptability. These advantages make the equipment a new choice for refractory brick production, and bring new opportunities and challenges for the development of the industry. In the future, with the continuous development of science and technology and the continuous expansion of application scenarios, it is believed that the screw press will play a more important role in the production of refractory bricks and make greater contributions to the realization of high-quality development of the manufacturing industry.