How does a refractory plant use a servo electric screw press to develop high value-added products?

Author: haloong Time: 2023-09-27 16:35:57

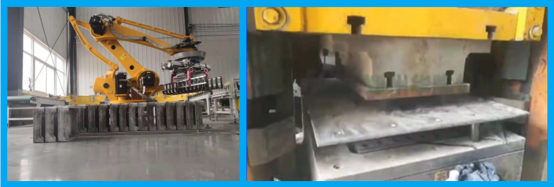

Taking a refractory material factory as an example, the factory introduced a servo electric screw press for the development of high value-added products. After the installation and commissioning of the equipment, the factory began to develop new products.

First, the factory conducted market research to understand the needs of customers and competitors. Based on the research results, the plant decided to develop a high-performance refractory brick product for use in the kiln lining of iron and steel enterprises. The refractory brick product is required to have high density, high strength, high wear resistance and anti-spalling properties.

Secondly, the factory carried out product design and mold making. According to customer demand and material performance characteristics, the shape and size of the firebrick are designed, and the three-dimensional modeling of the mold is completed by CAD software. In the production process, the factory adopts high-precision CNC machining equipment and strict processing technology to ensure the accuracy and quality of the mold.

Next, the plant carried out the product pressing work. The press process can be precisely controlled by the servo electric screw press, from pressure, speed to pressing time. In the pressing process, the factory also adopts advanced data monitoring and control system to ensure the quality and stability of the product.

Finally, the factory conducted product performance testing and customer feedback collection. After testing, the performance indicators of the refractory brick products are higher than those of competitors, and it has been recognized and praised by customers. At the same time, the factory has also established a perfect customer service system, timely solve customer problems and needs, improve customer satisfaction.

By using the servo electric screw press to develop high value-added products, the refractory material plant not only improves product quality and production efficiency, but also meets the market demand and customer demand, improving the competitiveness of the enterprise and economic efficiency. At the same time, the energy efficiency and environmental protection performance of the plant have also been improved, laying the foundation for the sustainable development of the enterprise.

In summary, the use of servo electric screw press to develop high value-added products for refractory materials factory has important significance and advantages. Through the introduction of advanced equipment and technology, refractory materials plants can improve product quality, production efficiency and value-added product variety, while reducing energy consumption and environmental pollution. In the future development, with the continuous progress of industrial technology and the changing market demand, the refractory industry will continue to face new challenges and opportunities. Therefore, refractory materials factories need to constantly introduce new technologies, strengthen research and development innovation, optimize production processes and improve product quality to meet market demand and improve the core competitiveness of enterprises. At the same time, refractory materials factory also need to pay attention to environmental protection and sustainable development issues, and actively take measures to reduce environmental pollution and improve resource utilization efficiency, to contribute to the sustainable development of the industry.