What are the advantages of using more servo electric screw presses for firebricks?

Author: haloong Time: 2023-09-22 10:09:24

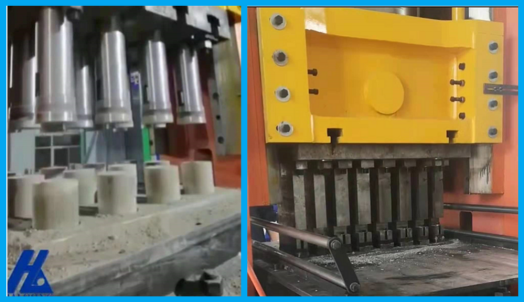

The use of a servo electric screw press for the production of refractory bricks has the following advantages:

High pressure, high precision, high efficiency: The servo screw brick press adopts the principle of screw extrusion mechanics, which can achieve high pressure extrusion molding, and has the characteristics of high precision and high efficiency. This device can extrude raw materials under high pressure to produce high-quality, high-density firebricks.

Wide range of application: servo screw brick press is suitable for firebrick manufacturing of various shapes and sizes, and can meet the production needs of different types and specifications of firebrick. In addition, the modular design of the equipment allows it to be flexibly adjusted according to production needs, adapting to different production environments and product requirements.

Energy saving and environmental protection: Compared with the traditional brick press, the servo screw brick press has better energy saving and environmental protection performance. Through the use of advanced servo systems and optimized structural design, the equipment can reduce energy consumption and reduce exhaust emissions, in line with the sustainable development strategy of today's society.

Good strike effect: servo electric screw press driven by servo motor, can achieve a single stroke of high and low speed free transformation, can simulate the manual strike process, to achieve suspended strike, at the same time install the blanking device, in the strike process can be at any time (multiple) exhaust, secondary blanking, speed, pressure, even hammer can effectively replace the ordinary brick press, effectively improve the production efficiency.

High control precision: servo motor control precision is high, the same batch of brick process parameters consistent, can achieve mass production, greatly ensure the consistency of the density and size of refractory brick, improve the refractory brick after forming pass rate.

Simple operation: servo electric screw press does not require mature pressure operators, just simple training, new people can be on the job. At the same time, only one person needs to press the weighing material feeding button, and one person can complete the forming process by taking bricks and palletizing. At the same time, the servo electric screw press is equipped with an emergency stop button, which can realize emergency braking at any time and improve production safety.

In summary, the use of servo electric screw press to produce firebrick has the advantages of high pressure, high precision, high efficiency, wide range of application, energy saving and environmental protection, good impact effect, high control accuracy, simple operation and so on. This equipment can meet the production needs of different types and specifications of refractory bricks, reduce energy consumption and reduce exhaust emissions, in line with the sustainable development strategy of today's society. At the same time, the modular design of the servo electric screw press allows it to be flexibly adjusted according to production needs, to adapt to different production environments and product requirements. In addition, the equipment also has the characteristics of high efficiency, can produce a large number of refractory bricks in a short time, improve the production efficiency and product quality of enterprises. Therefore, the use of servo electric screw presses is the ideal choice for refractory brick manufacturing enterprises.