What problems are prone to occur in the process of firebrick pressing?

Author: haloong Time: 2023-09-13 14:35:02

What problems are prone to occur in the process of firebrick pressing?

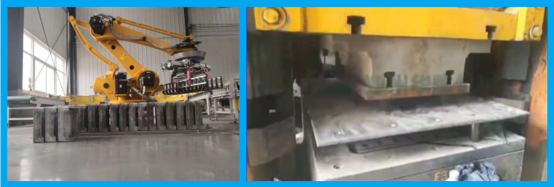

Firebrick pressing is an important link in the production of refractory materials, and it is also a process with high technical requirements. In the process of pressing refractory bricks, there may be some problems that affect the quality and production efficiency of refractory bricks. The following is to discuss the easy problems in the process of firebrick pressing.

Cracks appeared in the pressing process

Cracking is one of the common problems in the pressing process of firebrick. This is mainly due to the uneven force or improper drying of refractory bricks during the pressing process. The existence of cracks will reduce the strength and thermal stability of firebrick, and even affect its service life. Therefore, cracks should be avoided as much as possible during the pressing process.

The shape of the firebrick is irregular

The irregularity of the shape of firebrick after pressing is also one of the common problems. This is mainly caused by uneven press pressure or unreasonable mold design during pressing. The fire brick with irregular shape will cause uneven load to the kiln in use, which will affect the use effect of the kiln. Therefore, in the pressing process should try to avoid the appearance of irregular shape.

The firebrick has uneven density

The density of firebrick has an important influence on its quality and use effect. In the pressing process, due to the uneven density of the powder or the uneven pressure during pressing, the density of the refractory brick will be uneven. The use of refractory bricks with uneven density will affect the temperature distribution and thermal efficiency of the kiln, and even lead to kiln damage.

The firebrick is stratified

The delamination of refractory bricks in the pressing process is also one of the common problems. This is mainly caused by poor gas emission in the powder or unreasonable mold structure design. The existence of stratification will make the refractory brick easy to flake and crack in use, affecting its service life.

It is difficult to release the mold during the pressing process

The demoulding difficulty is one of the common problems in the pressing process of firebrick. This is mainly caused by unreasonable mold design or excessive pressure during pressing. Demoulding difficulties will not only affect the production efficiency, but also cause damage to the mold and affect its service life.

Refractory brick surface quality is poor

The surface quality of refractory brick has an important influence on its use effect and service life. In the pressing process, due to the poor quality of the die surface or the uneven pressure during pressing, the surface quality of the refractory brick will be poor. This will affect the thermal stability and corrosion resistance of refractory bricks in use.

In short, there are many problems in the pressing process of refractory bricks, which will affect the quality and production efficiency of refractory bricks. In order to solve these problems, it is necessary to take corresponding measures from the aspects of raw material selection, formula design, press production process, mold design, production operation, etc., to improve the technical level and management level in the process of firebrick pressing. At the same time, it is necessary to strengthen the quality control and supervision in the production process of refractory bricks, discover and solve problems in time, and ensure the quality and use effect of refractory bricks.