Servo electric screw presses help the refractory industry Industry 4.0

Author: haloong Time: 2023-09-08 14:35:11

In the refractory industry, the press is one of the most critical equipment. The traditional press usually adopts the mechanical or hydraulic transmission mode, but these modes have the problems of low efficiency and low precision. With the advancement of Industry 4.0, servo electric screw presses have gradually become the new favorite of the refractory industry. This article will introduce the application of the servo electric screw press in the refractory industry 4.0, as well as its characteristics of precise control and high efficiency.

Servo electric screw press is a kind of screw press driven by electric servo system. It is mainly composed of motor, reducer, nut and lead screw. When working, the motor receives instructions and drives the reducer, which then drives the nut and the lead screw to rotate and realize the precise control of the press. Compared to traditional presses, servo electric screw presses have higher accuracy and higher efficiency.

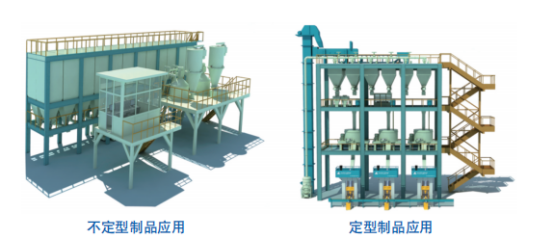

In the refractory industry, servo electric screw presses are mainly used for pressing various products. By precisely controlling every step of the pressing process, the servo electric screw press can achieve precise control of the size, density and strength of the product. This not only improves the quality and consistency of the product, but also reduces energy consumption and waste during production.

Application Case:

A refractory material production enterprise introduced a servo electric screw press for the production of various specifications of refractory bricks. After using the servo electric screw press, the enterprise has achieved precise control of the production of refractory bricks, the production efficiency has been increased by 30%, the cost has been saved by 20%, and the quality of the products is more stable.

Specifically, the servo electric screw press in this enterprise application plays the following advantages:

Production efficiency: The pressing cycle of the servo electric screw press is short, which can quickly complete the pressing and demoulding of the product. At the same time, due to its high-precision control ability, the qualified rate of the product has been significantly improved.

Cost savings: The energy consumption of servo electric screw presses is low, which can greatly reduce production costs compared to traditional hydraulic presses. In addition, due to its high precision and fast speed, it can achieve small batch and multi-variety production, which is conducive to reducing inventory and reducing capital occupation.

Stable quality: The servo electric screw press can achieve precise control of every link in the pressing process, making the size, density and strength of the product more stable. This not only improves the quality and consistency of the product, but also reduces the production of waste and defective products during the production process.

With the in-depth advancement of Industry 4.0, the refractory industry will pay more and more attention to the intelligence and automation of equipment. As a kind of high precision and high efficiency pressure processing equipment, servo electric screw press has a very broad application prospect. In the future, the servo electric screw press will play a more important role in the refractory industry, helping enterprises to achieve intelligent production, improve product quality and reduce production costs.

In short, the application of the servo electric screw press in the refractory industry 4.0 is of great significance. It can achieve high precision and high efficiency pressure processing, improve the quality and consistency of products, reduce production costs and reduce waste. In the future, with the continuous progress of technology and the continuous expansion of application scenarios, servo electric screw presses will play a more important role in the refractory industry.