A new breakthrough in the refractory brick market: the high value-added effect of the servo screw press

Author: haloong Time: 2023-09-07 15:35:33

Firebrick is a key material widely used in high-temperature industries, such as steel, cement, chemical and other industries. With the process of industrialization, the demand of the refractory brick market is growing, and it is also facing fierce competition. In order to stand out in the market, firebrick manufacturers need to seek new technologies and equipment to improve product quality, reduce costs and meet customer needs. As an advanced molding equipment, the servo screw press has brought new breakthroughs and high value-added effects to the refractory brick market.

Market situation analysis

The global refractory brick market shows a steady growth trend, mainly distributed in China, India, Russia and other countries and regions. In these areas, the development of steel, cement, chemical and other industries has spawned a huge market demand for refractory bricks. At the same time, the technological progress of these industries and the implementation of environmental protection policies have also put forward higher requirements for the refractory brick market.

In terms of the competitive landscape, the main players in the refractory brick market include domestic large refractory enterprises and well-known foreign enterprises. These enterprises compete in product quality, cost, service and other aspects, but the overall market pattern is relatively stable.

Existing problem

Although the refractory brick market is promising, there are the following problems:

Unstable product quality: Due to the limitations of traditional molding equipment, the quality and dimensional consistency of refractory brick products are difficult to ensure, affecting the use effect and production efficiency of customers.

Low production efficiency: The pressure of traditional molding equipment is uneven and the operation is cumbersome, resulting in low production efficiency and unable to meet the market demand.

High energy consumption and environmental pressure: Traditional molding equipment has high energy consumption, and environmental pressure is gradually increasing. In the refractory brick market, the main competitors include domestic large refractory enterprises and foreign well-known enterprises. These enterprises have their own advantages and disadvantages in terms of technology, products and brands. Among them, domestic enterprises have greater advantages in cost and service, while foreign enterprises have advantages in technology research and development and brand influence. However, the introduction of the servo screw press will change this pattern, because it has obvious advantages in improving product quality, production efficiency and reducing energy consumption.

High value-added effect analysis

The servo screw press has the following high value-added effects in the production of refractory bricks:

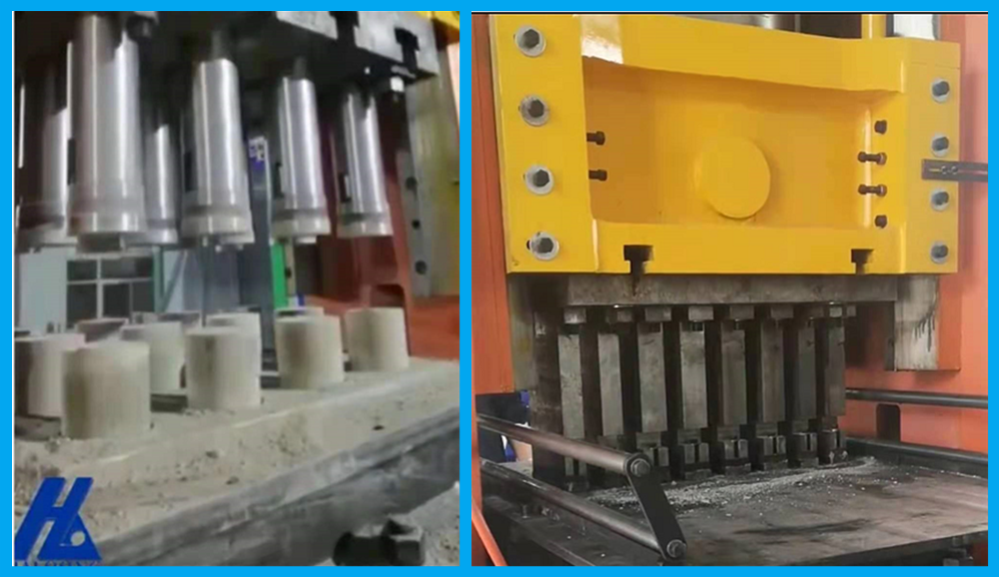

Improve product quality and consistency: Servo screw press adopts advanced servo drive system and screw extrusion mechanics principle, which can achieve high precision and high pressure pressing, thereby improving product quality and consistency. This helps to improve the production efficiency and product quality of customers and increase market share.

Improve production efficiency: servo screw press has the characteristics of fast response and high efficiency, which can shorten the pressing cycle, improve production efficiency and reduce production costs. This helps firebrick manufacturers increase production, meet market demand, and gain an advantage over the competition.

Reduce energy consumption and environmental pressure: The servo screw press adopts advanced energy-saving technology and modular design, which can reduce energy consumption and reduce exhaust emissions, and meet the requirements of environmental protection policies. This helps to reduce operating costs, improve corporate profits, and establish a green, environmentally friendly corporate image.

Promote technological progress and industrial upgrading: The introduction of servo screw press will promote technological progress and industrial upgrading of refractory brick manufacturing. Through the introduction of advanced equipment and technology, firebrick manufacturers can improve their own research and development capabilities and production levels, so as to meet customer needs and open up new market areas.

The high value-added effect of servo screw press in the refractory brick market is mainly reflected in improving product quality, production efficiency and reducing energy consumption. Its introduction will change the pattern of market competition and bring new opportunities and challenges to firebrick manufacturers. In order to gain an advantage in the market, enterprises need to keep up with the pace of technological progress, introduce advanced equipment and technology, and improve their research and development capabilities and production levels. Only in this way can we achieve sustainable development in an invincible position in the fierce market competition.