Reveal the secret of high added value of refractory brick: the application of servo screw brick press

Author: haloong Time: 2023-09-07 09:44:19

In the field of refractory brick production, the creation of high value-added products has been the pursuit of many enterprises. In order to achieve this goal, in addition to product design and material selection, the upgrading of production equipment is also particularly important. This paper will focus on the application of the servo screw brick press in the production of refractory bricks and reveal its secret of increasing added value.

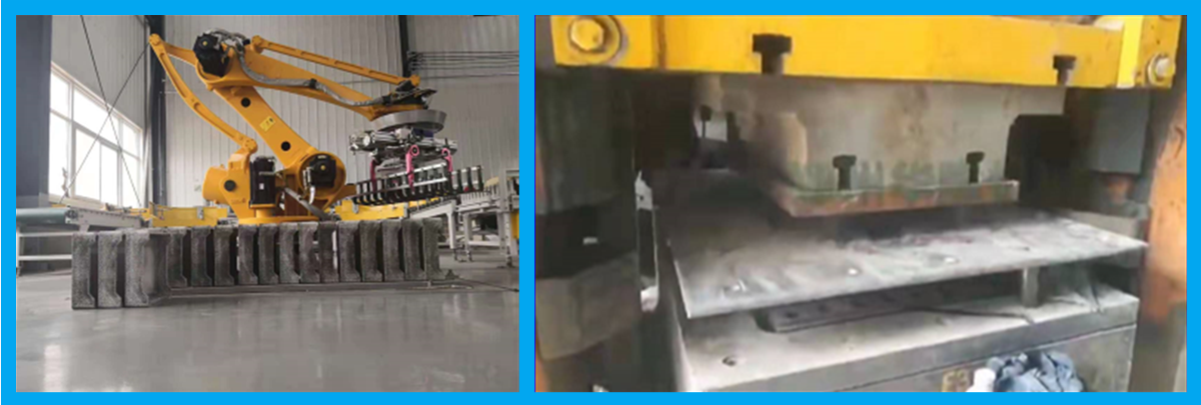

The servo screw brick press is an advanced refractory brick forming equipment, which adopts the principle of screw extrusion mechanics to extrude the raw materials under high pressure. This kind of equipment has the advantages of high precision, high pressure and high efficiency, and has a significant effect on improving the density, strength and consistency of refractory bricks. First of all, the working principle of the servo screw brick press gives it a significant advantage in the production of refractory bricks.

Compared with the traditional brick press, the servo screw brick press adopts the advanced screw extrusion mechanics principle, which can compress the raw materials more evenly and avoid the difference in product quality caused by the uneven pressure of the traditional brick press. This not only helps to improve the physical properties of refractory bricks, but also reduces the scrap rate, thereby increasing the added value of the product.

Secondly, the structural characteristics of the servo screw brick press also help to enhance the added value of refractory bricks. The equipment uses high-strength materials and precision machining technology to ensure the stability and long service life of the equipment. In addition, the servo screw brick press also has a flexible modular design, which can easily adjust the equipment parameters according to the production needs, to adapt to different types and specifications of refractory brick production. This flexibility and adaptability enables companies to respond quickly to market changes and meet customer demand for diverse products.

In order to further tap the potential of the servo screw brick press to enhance the added value of refractory bricks, the production process can focus on the following aspects:

Improve production efficiency: By optimizing equipment configuration and production process, improve the production efficiency of servo screw brick press and reduce the production cost per unit of product. This helps to improve the competitiveness of enterprises in the market, so as to obtain more market share.

Strengthen the degree of automation: the introduction of advanced automation technology to achieve remote monitoring and intelligent control of servo screw brick press. This helps reduce manual intervention, reduce operating costs and improve stability in the production process.

Focus on energy saving and environmental protection: In the equipment design and production process, pay attention to energy saving and environmental protection treatment, in line with market demand and sustainable development strategy. This can not only reduce the operating costs of enterprises, but also help to enhance the corporate image and product brand value.

Case study:

After a refractory production enterprise introduced the servo screw brick press, after a period of use, it was found that the equipment played a significant role in increasing the added value of the product. First of all, the high pressure molding technology of the equipment makes the density and strength of refractory bricks have been greatly improved, and the quality and stability of the products have been recognized by the market. Secondly, the production efficiency of the servo screw brick press is higher than that of the traditional brick press, which reduces the production cost of the enterprise and enhances the market competitiveness. In addition, the equipment pays attention to energy saving and environmental protection in the production process, which is in line with market demand and sustainable development strategy, and further enhances the corporate image and product brand value.

The application of servo screw brick press in refractory brick production is undoubtedly an important way to enhance the added value of products. Its advanced working principle, structural characteristics and flexible modular design enable enterprises to obtain higher efficiency and more stable product quality in the production process. At the same time, focusing on production efficiency, automation, energy saving and environmental protection can further tap the potential of the servo screw brick press and create more value for the enterprise. This paper hopes to provide some useful reference and enlightenment for related enterprises by discussing the application of servo screw brick press in refractory brick production.