Electric screw brick press: the saviour of the environment of refractory brick workshop and the Newark of dust problems

Author: haloong Time: 2023-09-05 10:35:06

In the firebrick workshop, environmental problems and dust problems have always been difficult problems in the production process. The traditional brick press will produce a lot of dust in the production process, which not only affects the sanitary environment of the workshop, but also poses a threat to the health of the workers. The emergence of the electric spiral brick press has brought a new solution for the refractory brick workshop, which not only improves the working environment, but also becomes a dust problem.

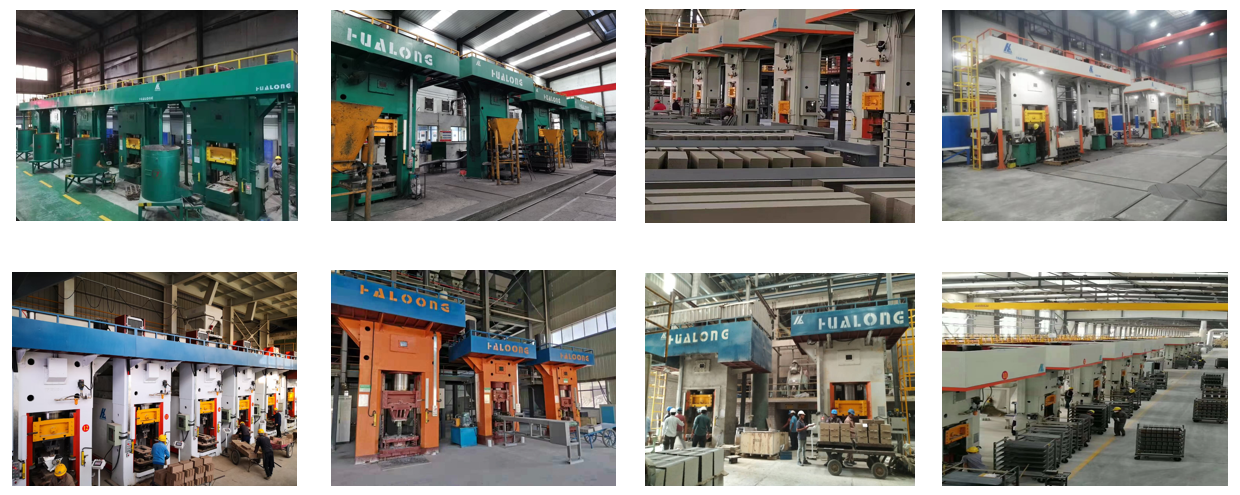

The electric screw brick press adopts advanced electric screw brick technology, and drives the screw rod by the motor to press the refractory brick raw material into dense bricks. The equipment is simple in structure, easy to operate, and can effectively reduce the dust emission of the workshop. Compared to traditional brick presses, electric screw brick presses have a higher pressing density and less dust emissions, bringing significant environmental improvements to firebrick workshops.

In addition to improving the working environment, the electric screw brick press also improves production efficiency and product quality. Through the use of electric screw brick presses, the production efficiency of firebrick workshops has been significantly improved, while the number of unqualified products has been reduced. This not only improves the economic efficiency of enterprises, but also saves a lot of time and energy for workers.

In addition, the electric screw brick press also has excellent energy saving and environmental protection performance. Because it is driven by an electric motor, it is more energy efficient than the traditional brick press. At the same time, because it reduces dust emissions, the impact on the environment is also reduced. These advantages make the electric screw brick press an ideal choice for environmental protection and energy saving in refractory brick workshops.

In terms of operation and maintenance, the electric screw brick press is also very convenient. The operator only needs to follow the instructions to operate, and can easily master the operation method of the equipment. At the same time, the maintenance of the electric spiral brick press is also relatively simple, only need to check and lubricated the key parts regularly, to ensure the stable operation of the equipment.

In short, the electric screw brick press is the savior of the refractory brick workshop environment and the Newark of dust problems. Through the use of this equipment, not only can improve the working environment, improve production efficiency and product quality, but also achieve the goal of energy conservation and environmental protection. Therefore, it is recommended that electric screw brick presses be used in firebrick workshops to solve environmental problems and dust problems and achieve more sustainable and efficient production.