Precise control, greatly improve the production efficiency of the refractory brick press

Author: haloong Time: 2023-09-02 14:35:27

With the continuous acceleration of the industrialization process, the demand for refractory materials is also increasing. In the production of refractory materials, brick pressing is a key process. In recent years, with the continuous progress of science and technology, a refractory brick press with precise control function came into being, which greatly improves production efficiency and product quality.

One: The importance of refractory materials and the limitations of traditional brick press

Refractories are widely used in metallurgy, construction, chemical industry and other fields, and their quality is directly related to the stability and safety of industrial production. The production of refractory is inseparable from the consolidation processing of raw materials, and the traditional brick press has some limitations in this process. For example, it is difficult to fully control the dimensional accuracy of the block, low production efficiency and high energy consumption, and a new solution is needed.

Two: the application and advantages of precise control technology

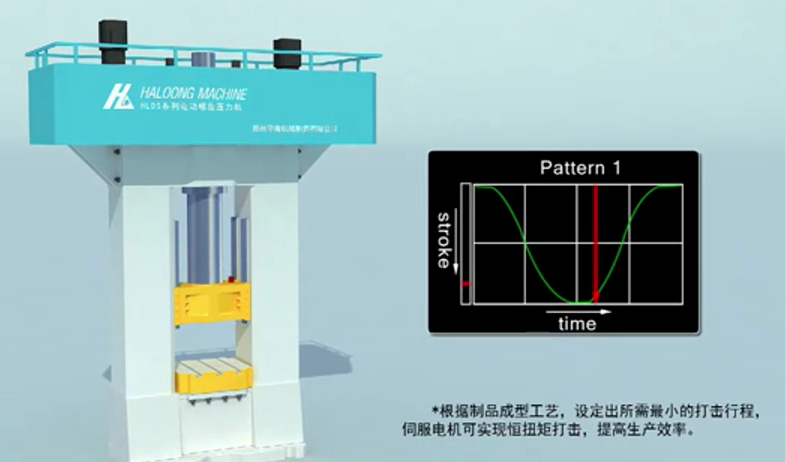

Recently, a precision control function of the refractory brick press appeared, the machine uses advanced automation technology and sensor devices, can achieve the precise control of the block size, density, pressure and other parameters. This brick press can not only greatly improve the production efficiency, but also ensure the stability and consistency of product quality.

Three: The advantages of precise control technology

First of all, the machine improves the assembly accuracy and construction effect of refractory materials by precisely controlling the size of the block, so that each block meets the standard specifications. Secondly, because the precision control technology can adjust the density and pressure of the block, the waste of raw materials is reduced and the production cost is reduced on the premise of ensuring the strength of the material. Moreover, the highly automated operating system also greatly reduces the labor intensity of the operator and improves the safety and stability of the operation.

Iv. Prospect and conclusion

Precision control technology has a broad application prospect in the field of refractory brick press. With the continuous progress of science and technology and the continuous pursuit of production efficiency and quality requirements, this advanced brick press will become an indispensable tool in the production process of refractory materials. For the refractory industry, it means higher competitiveness and broader development space.

The refractory brick press with precise control and greatly improved production efficiency is an important technological innovation in the field of refractory production. It greatly improves production efficiency and product quality by precisely controlling parameters such as block size, density and pressure. With the continuous development of technology, it is believed that this advanced brick press will play a huge role in the refractory industry and promote the industry to a higher level.