How to optimize the process to ensure the consistency of firebrick products

Author: haloong Time: 2023-08-11 09:39:18

As a common high temperature resistant material, firebrick is widely used in metallurgy, construction, chemical industry and so on. However, in the production process, due to the changes of manual operation and process parameters, it is difficult to ensure the consistency of firebrick, which affects its quality and performance. The emergence of CNC press for the Internet of Things provides a new way to solve this problem.

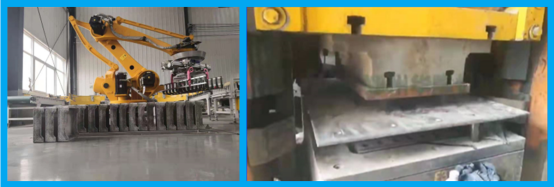

The Internet of Things CNC press is a kind of intelligent equipment formed through the combination of Internet of Things technology and traditional CNC press. Its main features include automatic control, real-time monitoring and feedback, and data analysis. These characteristics provide convenient conditions for optimizing the process.

Second, the significance of optimizing the process to improve the consistency of firebrick products Improve production efficiency: by optimizing the process, you can reduce the error of manual operation, improve production efficiency, and reduce the unqualified rate of products. Ensure the stability of product quality: by controlling the process parameters, the sintering temperature, time and pressure of each product can be accurately controlled to ensure the stability and consistency of product quality. Saving energy and raw materials: Optimizing the process can reduce the waste of energy and raw materials and improve the utilization of production resources.

Real-time monitoring and feedback: The Internet of Things technology can monitor the operating status of equipment, process parameters and product quality indicators in real time, and feed the data back to the operator. Through real-time monitoring, problems are found and adjusted in time to ensure the stability and consistency of the process.

Data analysis and optimization: The Internet of Things CNC press can record and store a large number of production data, through data analysis and mining, find out the problems and bottlenecks in the process, and make corresponding optimization adjustments to improve the consistency of refractory brick products.

Automatic control: The CNC press of the Internet of Things can be automatically controlled according to the preset process parameters, reducing the error of human intervention and improving the accuracy and stability of the process. The emergence of CNC press of Internet of Things provides a new idea and method for optimizing the process and improving the consistency of firebrick products.

Through real-time monitoring and feedback, data analysis and optimization, automated control and other means, the process can be continuously improved to ensure the consistency of refractory brick products, improve product quality and enterprise competitiveness. In the future development, we should further give play to the advantages of Internet of Things technology, promote the wide application of Internet of Things CNC press in industrial production, and provide more support for the upgrading of the refractory industry.