Analysis on the reasons and importance of good consistency of firebrick products

Author: haloong Time: 2023-08-11 09:32:11

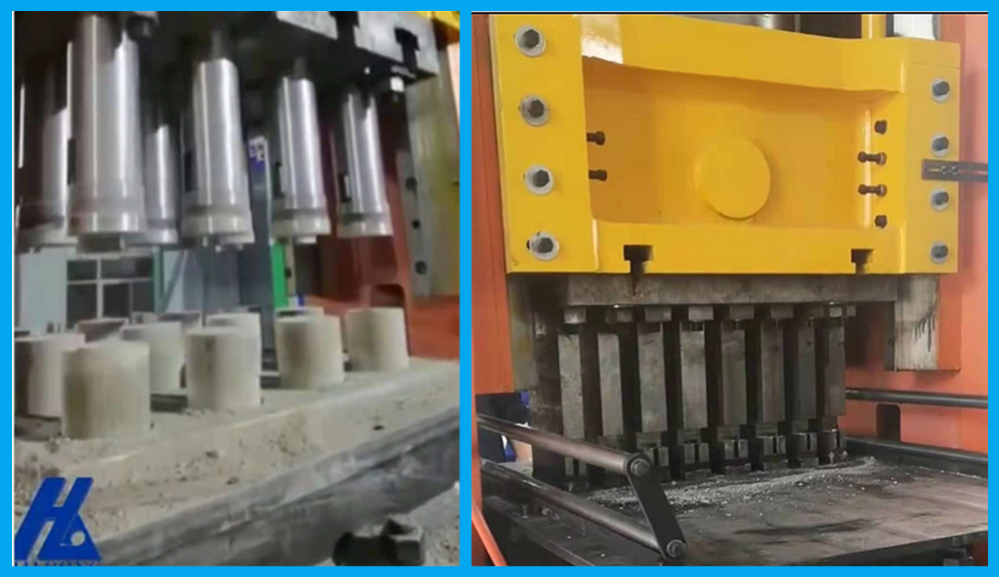

With the continuous development of technology, the combination of the Internet of Things and numerical control technology has become a trend in many industries. In the field of industrial manufacturing, the application of the Internet of Things CNC press plays an important role in ensuring the consistency of firebrick products. This paper will explore the reasons and importance of iot CNC press in improving the consistency of firebrick products.

The use of CNC press can realize the automation of the production process, and can be precise control, avoiding the impact of human factors on product consistency. Using the Internet of Things technology, the press can precisely control all aspects of the forming, heating and cooling of the refractory brick to ensure the stable quality of each refractory brick. This automated production method greatly improves the consistency of refractory bricks, reduces batch differences, and ensures that products meet standard requirements.

The intelligent monitoring function of the Internet of Things CNC press can collect the data of each process in real time, and through the monitoring and analysis of the pressure, temperature, time and other parameters, the problems existing in the production process can be found, and the machine parameters can be adjusted in time. This real-time feedback mechanism effectively reduces errors and deviations in the production process and improves the consistency of each firebrick.

Third, traceability system to ensure quality traceability in the production process can be connected with the enterprise's management system, forming a complete traceability system. All production data and process parameters can be recorded and stored for easy follow-up and traceability. If there is a quality problem, the source of the problem can be traced according to the data, and corrective action can be taken to improve the consistency and quality of the product.

Ensuring the consistency of firebrick products is of great significance in the field of industrial manufacturing:

Improve product quality: consistent firebrick products can better meet the needs of use, with more stable performance and longer service life.

Reduce production costs: Good consistency of firebrick products reduces the failure rate and repair rate of the product, thereby reducing production costs and material waste.

Enhance brand image: Providing good consistency of firebrick products can enhance the advantages of enterprises in market competition and establish a good brand image and reputation.

Meet safety standards: Consistent firebrick products can ensure the safety and stable operation of industrial equipment and avoid potential safety hazards.

The application of Internet of Things CNC press provides an effective solution to ensure the consistency of firebrick products. Through the establishment of automated production, real-time data monitoring and traceability systems, the consistency of products can be improved and play an important role in the industrial manufacturing process. Ensuring the consistency of firebrick products not only has economic benefits for enterprises, but also has a positive impact on the development of the entire industry and the safety needs of users.