Remote monitoring service of servo screw press helps the intelligent transformation of resistant material enterprises

Author: haloong Time: 2023-08-09 09:58:44

With the continuous development of society and the rapid development of science and technology, enterprises have higher and higher requirements for production efficiency and quality control. Especially in the resistant material industry, such as steel, building materials and other fields, there are extremely strict requirements for the processing of raw materials and the quality of finished products. In order to meet these needs, resistant material companies are actively promoting intelligent transformation, and the use of servo screw press remote monitoring services to improve production efficiency and achieve full control.

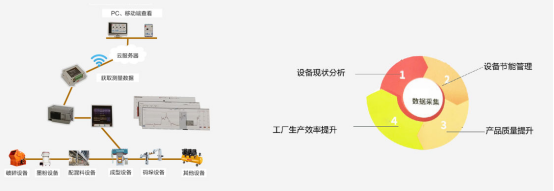

Remote monitoring service of servo press is an innovative solution based on Internet and Internet of Things technology. Through the installation of sensors and equipment monitoring systems, key data and status information are transmitted to the remote monitoring center in real time. The company can monitor the operation of the press anytime and anywhere through terminal equipment such as computers, mobile phones or tablets, and carry out remote operation and adjustment to achieve full control.

First, remote monitoring services for servo screw presses can improve production efficiency. Traditional press operation requires manual involvement and is limited by time and space. Through the remote monitoring service, the staff can remotely monitor the operating status of the press, find problems and make adjustments in time, and avoid the loss caused by the shutdown of the production line. In addition, due to the collection and analysis of real-time data, enterprises can carry out data mining and optimization to further improve production efficiency.

Secondly, the servo screw press remote monitoring service can realize the full control of quality control. Through the remote monitoring system, enterprises can monitor the press's working status, pressure changes and other key indicators in real time, and compare with the standard. In case of abnormal situation, the system will immediately alarm and take appropriate measures to ensure the quality and stability of the product.

At the same time, a large amount of data can be recorded and stored through the remote monitoring service, which provides a basis for subsequent quality tracking and analysis. In addition to increased productivity and quality control, remote monitoring services for servo screw presses offer additional benefits. First, it can reduce the occurrence of human errors and accidents. The automated monitoring system can respond to emergencies more quickly and accurately, and take appropriate measures to reduce risks caused by human operations.

Secondly, through remote monitoring, enterprises can timely understand the use of equipment and maintenance needs, and carry out preventive maintenance in advance, reducing downtime and repair costs.

To sum up, the remote monitoring service of servo screw press helps resistant material enterprises achieve intelligent transformation, improve production efficiency and quality control level, and bring many benefits. For the pursuit of efficient, safe and sustainable development of resistant material enterprises, investing in servo screw press remote monitoring services is undoubtedly a wise choice. Let's move towards a smart factory and enjoy the full control of production!