Energy saving and environmental protection, servo press leads the sustainable development of the skateboard brick industry

Author: haloong Time: 2023-08-04 11:31:07

With the increasingly severe global environmental problems, sustainable development has become the focus of all walks of life. As an important part of the building materials industry, the skateboard brick industry is inevitably facing environmental pressure. However, the application of servo presses is leading the skateboard brick industry to the path of sustainable development.

Energy-saving effect is remarkable: servo press with its automatic control and energy optimization design, to achieve a high energy efficiency. Compared with the traditional hydraulic press, the servo press can control the pressure and working time more precisely during the working process, avoiding the waste of energy. This energy-saving effect not only helps to reduce energy consumption, reduce production costs, but also meets environmental protection requirements and reduces the loss of natural resources.

Reduce scrap rate: The servo press has high accuracy and stability in the production process, which can ensure that the size, shape and quality of each skateboard brick meet the standard requirements. Compared to traditional presses, servo presses control the force and position of the pressure more precisely, avoiding waste products caused by improper operation or mechanical problems. This not only reduces the waste of materials, but also improves the quality of products, enabling companies to better meet market demand.

Reduce pollution emissions: Traditional hydraulic presses often produce large noise and vibration in the work, but also accompanied by leakage and pollution of hydraulic oil. The servo press uses electric drive, the noise and vibration in the working process are greatly reduced, and there is no hydraulic oil leakage problem, which effectively reduces the pollution to the environment.

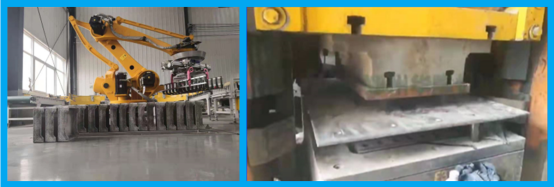

Improve production efficiency: servo press relies on advanced control system and intelligent technology, with a higher degree of automation, production efficiency is significantly improved. The operator can achieve automatic loading, pressure application and unloading of the template through simple parameter setting, which shortens the production cycle and improves the production efficiency.

Enhance market competitiveness: As a pioneer in the skateboard brick industry, the introduction of the advantages of energy-saving and environmental protection, reducing scrap rate and improving production efficiency brought by the servo press will make the enterprise in a more favorable position in the market competition. Consumers are paying more and more attention to environmental protection and sustainable development, and skateboard brick products with energy saving and reliable quality will be more competitive in the market.

Conclusion: Servo press with its outstanding advantages of energy saving and environmental protection, leading the sustainable development of the skateboard brick industry. By reducing energy consumption, reducing waste generation and emissions of pollutants, servo presses not only meet the requirements of environmental protection, but also improve production efficiency and product quality, making enterprises more competitive in the market. Choosing a servo press is a wise choice for the skateboard brick industry to move towards sustainable development.