The full automatic of firebrick you have to consider these

Author: haloong Time: 2018-10-22 10:22:14

With the development of more and more refractory enterprises and the increasing business demand, more and more refractory enterprises have put automation production of firebrick the on the agenda.

Automatic upgrade is not a simple station or machine replacement can be completed, but an extremely complex system engineering. The automation production of firebrick should be done according to the capacity, starting from the relatively mature automation technology, starting from the plant urgent to upgrade the reconstruction of the site, and gradually.

As a refractory enterprises to carry out automation production line of firebrick, then you should give priority to the following three aspects of planning

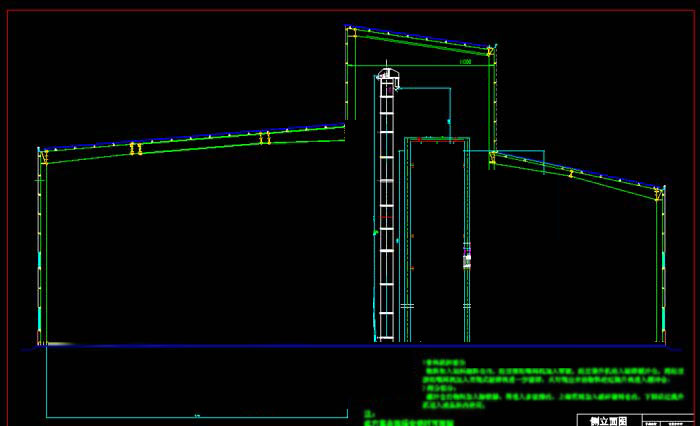

plant planning

Refractory enterprises according to their production capacity plan, to automation equipment agreed to make plans. Based on their own plant area, plant height to determine whether the need to rebuild or expand the plant.

Baching system automation

Due to the requirements of environmental protection and dust-free workshop, the automation of batching is the first step of the full automatic transformation of firebrick. Refractory enterprises need to take into account the output targets in the planning.

Plan out the batching building structure, the location of the batching building, and the baching capacity, and also some detailed problem.

Automation of press machine

Double disk friction press change to numerical control automation, is currently the most refractory material the first step of enterprise automation reform, the press is a core refractory brick molding equipment, relationship between the quality and yield of refractory brick, because of the double disk friction press energy intensive, high noise, low efficiency, the worker labor intensity is big, the friction press is eliminated by industry first molding equipment, in order to realize the automation in the process of seamless docking, the numerical control transformation of press is also must be carried out.

other parts:

Feeding automation

Can realize intelligent weighing and feeding, saving a weighing and feeding worker.

Automatic brick picking, checking and stacking

Auto picking: can design the mechanism to take the brick or the robot to take the brick.

Auto checking: It is connected with press machine and mechanical arm to form a set of automatic checking and stacking system for refractory products.

Automatic stacking: robot stacking, high efficiency, accurate. (can be customized according to product size, weight and production site condition)

Every enterprise has its own investment plans for automation. Firebrick automation is not a step to be put in place, is a long-term process, each enterprise can be based on their actual situation gradually. But the first three are the first things most businesses consider automation to do.

Whether it is to achieve semi-automatic production of firebrick or full automatic production of firebrick. Through automatic transformation, the company can guarantee the consistency of product quality, improve the quality of brick and enhance the competitiveness of products. As the production process improved, the capacity was greatly activated. The automatic production of firebrick is the inevitable development direction of refractory enterprises, which will bring more changes and opportunities to refractory enterprises.